Rules for Getting a Pacific Pride or CFN Card in Oregon

What are the rules for getting a Pacific Pride and CFN Cardlock Card in Oregon?

Star Oilco is a proud independent Franchisee of Pacific Pride

Pacific Pride fueling is a wholesale cost plus way to buy fuel. With the crazy market conditions getting 24 hour access to fuel has a renewed appeal to both individuals as well as businesses. Today the price difference between retail gas stations and wholesale prices at CFN and Pacific Pride sites in part of the state of Oregon provides a huge price value for small businesses. Add to that the convenience of getting out of gas lines and being able to fuel 24 hours a day, 7 days a week, 365 days a year is a big value add for commercial cardlock over retail gas stations.

Pacific Pride and CFN cardlock both use a cost plus from the commercial wholesale rack prices to determine what you pay for fuel.

Avoid the volatility of retail credit card mark up with a cost plus agreement and a Star Oilco cardlock card.

Call Star Oilco and ask for a representative quote to see what CFN and Pacific Pride Cardlock costs compared to other fleet cards used at retail gas stations charging a credit card mark up. Also look at what a small business can benefit from with the security features of cardlock over giving your drivers unsecured credit cards.

Many small businesses wonder what it takes to use a stand-alone cardlock location. As wages rise, the cost of full serve retail gas stations rise too. In contrast, stand-alone commercial fueling stations have little wait and 24 hour access, which save business owners time and money. Star Oilco makes it easy to set up with Pacific Pride in Oregon.

Self-serve diesel fueling is legal in Oregon

Self-serve gasoline is restricted in Oregon

Here are the rules for self-serve gasoline in Oregon:

Oregon has legalized the option for any consumer to fuel their own car at a gas station. But a 24-7 stand alone self serve gasoline option like cardlock is not legal in Oregon without a business license or purpose. So though you can pump your own gasoline at a retail gas station, you cannot use commercial cardlock without being a business.

Diesel is legal for self serve throughout the state of Oregon. Gasoline is restricted in the more populated counties of Oregon except in certain cases. Commercial fleet fueling is one of the exemptions allowed, enabling a business to get its drivers out of gas lines and cut the labor wasting wait at retail gas stations.

Self-serve diesel has always been legal in Oregon and often cheaper at a commercial cardlock throughout the state. Anyone in Oregon who only uses diesel can get a Pacific Pride or CFN card for personal use.

Gasoline, on the other hand, has some rules that are regularly enforced. Self-serve gasoline is allowed in several rural counties in Oregon outside of the I-5 corridor. Self-serve gasoline in the more populated parts of Oregon is available at a retail gas station only if they offer full serve during business hours.

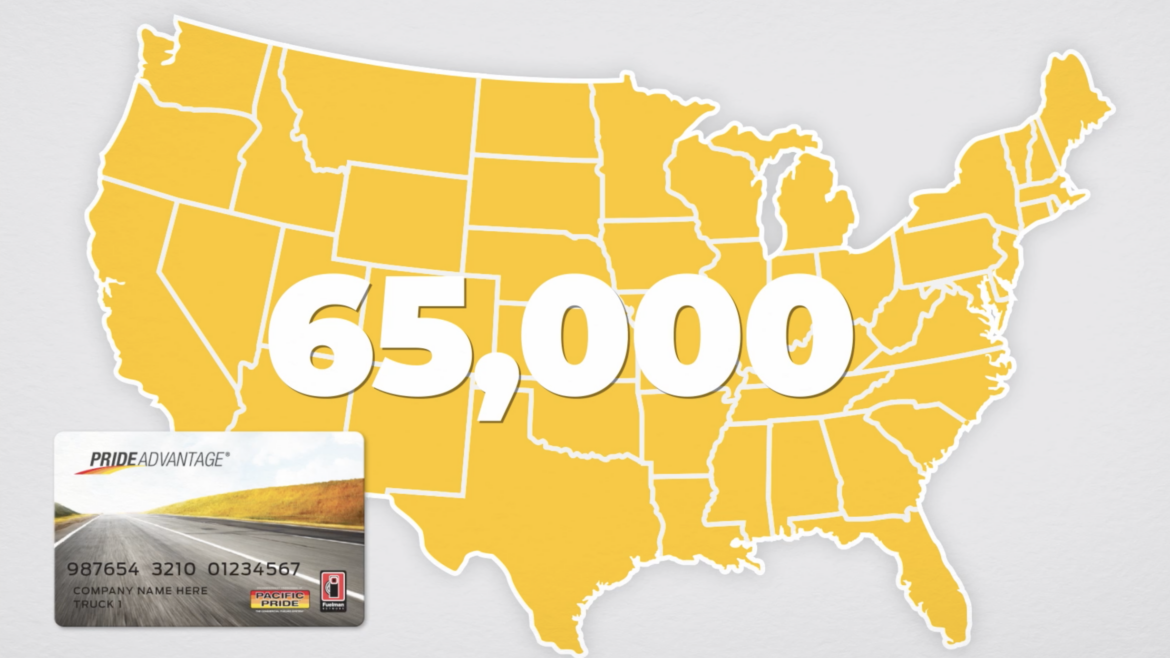

If you operate a company vehicle, commercial cardlock is the best way to upgrade your fleet security from fuel theft and seize control of corporate and small business fleet fueling. We can serve your business all around the United States. In Oregon though, gasoline is not legally dispensed without a few required safety precautions.

For commercial uses, Pacific Pride, CFN, Comdata, Voyager and other Commercial Cardlock networks are allowed for businesses in Oregon. If you are fleet operator or an individual outside of Oregon, these requirements do not apply in your home state. If you substantially operate in Oregon, the state Fire Marshall will expect these rules to apply to you.

What are the rules for using commercial cardlock in Oregon?

- Business purpose required for gasoline cardlock use in Oregon (not any other state).

- If you are only using diesel, commercial cardlock is available to everyone (individuals and businesses).

- If you are planning on fueling gasoline vehicles, you must be a business (or use it for commercial use).

- To access gasoline at cardlock in Oregon, you must be able to prove that you use over 900 gallons of fuel a year.

- To access gasoline at cardlock in Oregon, someone in your business must take a Oregon Fire Marshall Safety Test.

- Message Star Oilco below for a copy of the Oregon Fire Marshall Safety Test

If you have questions about Pacific Pride, CFN, or other cardlock systems, please don’t hesitate to contact us with any questions you may have. Star Oilco has a long tradition of making cardlock easy for businesses large and small. In particular, we specialize in helping you secure fuel usage to eliminate fuel theft and reduce any chance or opportunity for thieves.

To get access to Pacific Pride and CFN locations in Oregon, the first step is to open an account with Star Oilco.

Message Star Oilco below to get started with opening an account to save time and money while fueling.

For more information about how to use commercial cardlock to secure your business from theft, please also check out Star Oilco’s white paper on knocking out fuel theft by implementing a No Tolerance Fuel Theft Policy in your business at www.NoMoreFuelTheft.com.