Bulk Transporter Article on Star Oilco B99 Biodiesel use

Star Oilco graces the pages of Bulk Transporter Magazine.

Read the Bulk Transporter Magazine article about Star Oilco’s pioneering use of B99 Biodiesel in 105,500 GVW petroleum truck and trailers in the Pacific Northwest.

You can read the article by following the link below.

Star Oilco delivers sustainable fuels to Oregon in near-zero carbon trucks

If you want to talk about what Star Oilco has been doing with B99 as a major transportation fuel we look forward to talking.

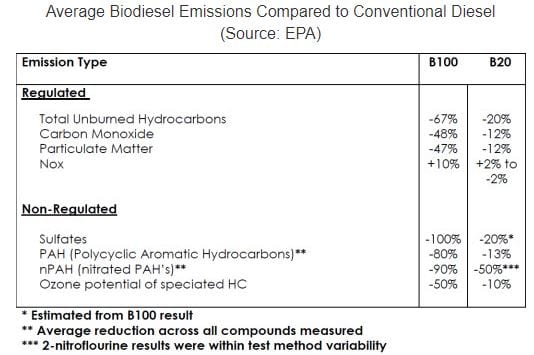

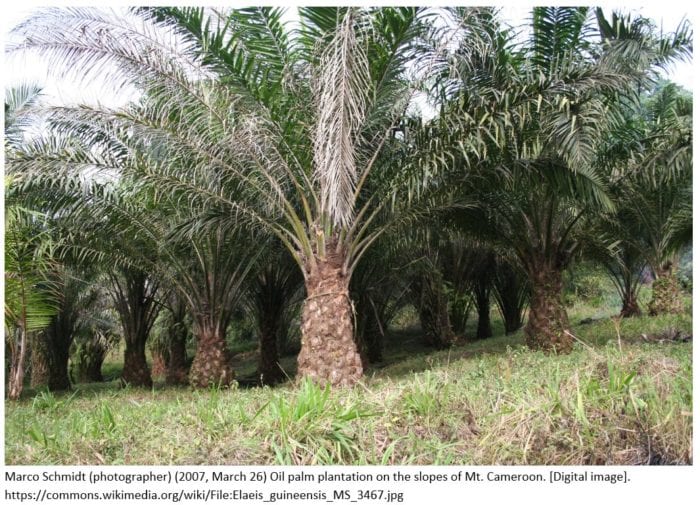

When you use biodiesel, you’re using CO2 that is being captured by the growing plants or the waste. This is current CO2 you aren’t adding to the net sum in the environment.

When you use biodiesel, you’re using CO2 that is being captured by the growing plants or the waste. This is current CO2 you aren’t adding to the net sum in the environment.

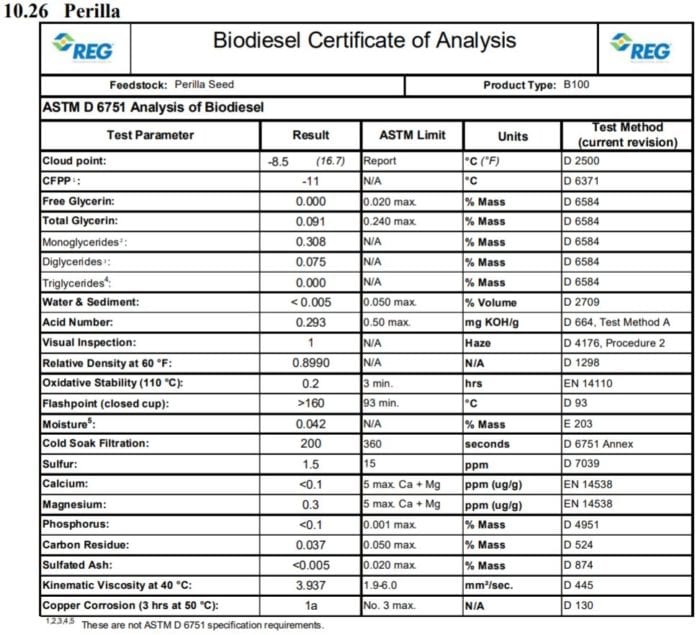

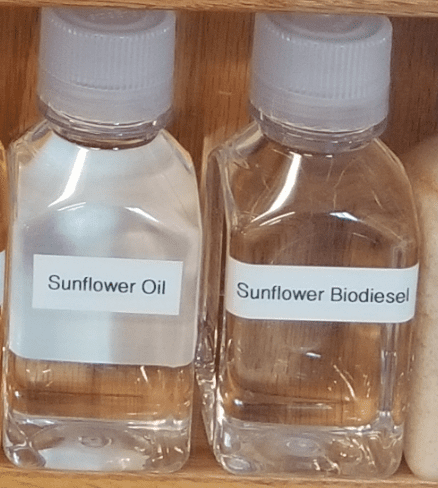

is different from other forms of fat and tallow. It tends to have less saturated fat. According to

is different from other forms of fat and tallow. It tends to have less saturated fat. According to

It is native to India and China in the mountainous regions and cultivated in China, Korea, Japan, and India. Introduced varieties of this plant are considered a weed in the United States and go by the common names Chinese basil, wild basil, perilla mint, beefsteak plant, purple perilla, wild coleus, blueweed, Joseph’s coat, and rattlesnake weed. This herb grows easily unattended, but is toxic for cattle and horses.

It is native to India and China in the mountainous regions and cultivated in China, Korea, Japan, and India. Introduced varieties of this plant are considered a weed in the United States and go by the common names Chinese basil, wild basil, perilla mint, beefsteak plant, purple perilla, wild coleus, blueweed, Joseph’s coat, and rattlesnake weed. This herb grows easily unattended, but is toxic for cattle and horses.