On-Site Refueling in Oregon

Wet Hose Fueling and Mobile On-Site Diesel Delivery in the Pacific Northwest.

If some days you have more work than drivers…

Mobile On-site refueling or “Wet Hosing” is a solution that will push more money to your bottom line and reduce stress on your drivers. Star Oilco can also merge our mobile onsite refueling service with our national Fleet Card system.

One bill, labor saving in town and secured fleet fueling over the road.

Top Five Reasons to Use Wet Hosing for your Fleet Diesel Fueling

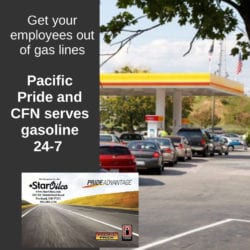

On-site refueling or “Wet Hosing” is a preferred method for fueling these days. Fleets of all sizes prefer getting their fleet fueling delivered after hours in their yard. The reasons are numerous but at the top of the list, labor is the driving force behind it.

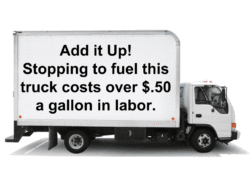

Shaving off even fifteen minutes of labor–which is one of the two highest costs for most fleets, right after diesel–can have a huge payback to the bottom line.

If your fleet is consistently on overtime or short that one extra hour of legal driver time, picking up fifteen to thirty minutes per truck a few times a month can be a huge opportunity. On top of that fleet fueling, your diesel can also save considerably just by controlling where you pay your fuel taxes (Oregon PUC is tax exempt on the fuel bill, while Washington cardlock and truck stops are paying nearly $.50 a gallon in Washington diesel road tax). Though you are paying IFTA, why pay the tax earlier than you need to.

Call Star Oilco if you have questions and want to examine the payback value of Mobile On-site Refueling compared against your current vendor for diesel. You might be surprised how much it will save you in time, money and management effort.

Five Reasons your fleet should use Mobile On-site Refueling:

- Driver Time – The most valuable resource your fleet owns.

- Truck drivers are a limited resource, and they cost more than you can usually measure in money alone. Without calculating the lost productivity of your truck, you are paying over $10 each time you allow your drivers to stop for fuel. Just the out of route, stopping, and getting back on the road time will put refueling your own trucks at a half hour of lost time. As the average fill up we see is under 50 gallons fueling your own trucks will cost you $.20 to $1 a gallon in labor costs alone.

- One More Stop – Picking up productivity in your fleet.

- Getting drivers on the road and without a reason to be out of route pays back dividends. If you pay productivity bonuses, your most productive drivers will thank you as well. Even in fleets where pay is by stop, not based on hourly wages, the ability those few times a year when drivers are so busy they are bumping up against DOT work rules, they will thank you for the convenience of being ready to go the start of each shift and not having to worry about that one more stop on the way back to base. A few extra stops a year is often worth thousands of dollars to your bottom line–more than a cost of a tank of diesel.

- Save on the Cost of Diesel

- Today the price of diesel at gas stations, truck stops, and other retail options is high compared to wholesale rack averages. It is not uncommon for our customers to get an extreme labor savings with Mobile Onsite Fueling while also saving on the cost of diesel at the end of the month. If you are using a credit card to buy fuel, the added Credit Card pricing of diesel is usually $.10 or more cents a gallon. Cut out the retail mark up on fuel and get a cost-plus deal with a true wholesale diesel seller delivering into your yard after hours.

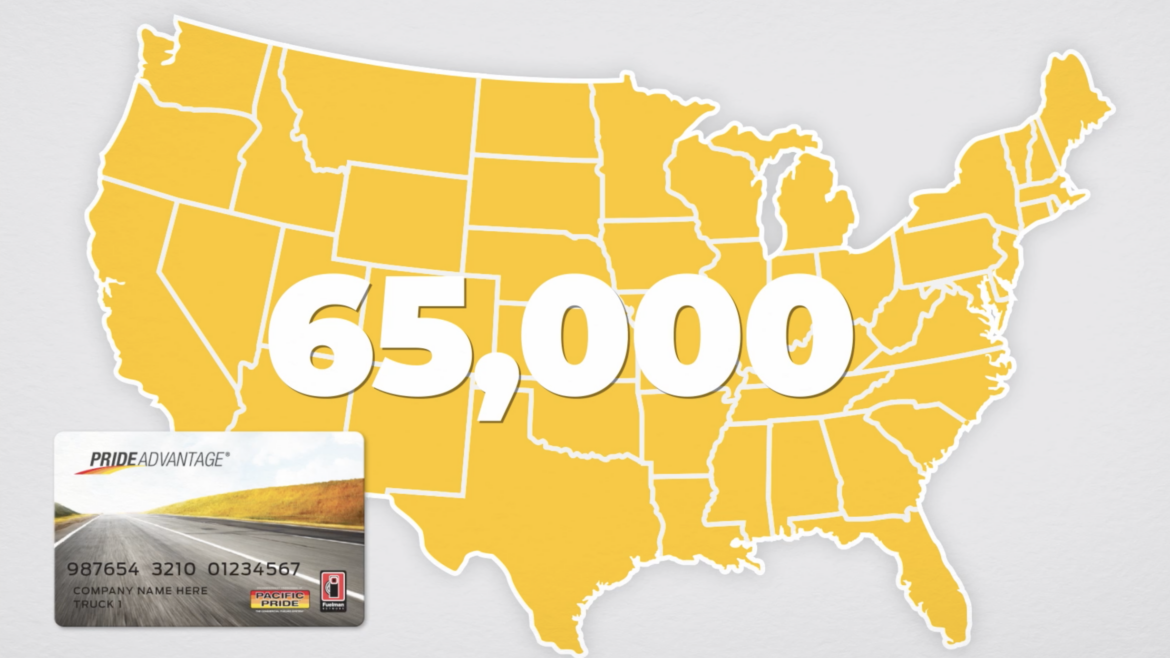

- Easily Integrates with cardlock and other fleet cards onto one bill easily.

- If you have a major hub with a critical mass of trucks in town, wet-hosing y

our fleet can pay back rapidly. Even if the majority of your fleet is over the road and out of town, on-site refueling can be a money saving proposition. You can also integrate it seamlessly with a Pacific Pride, CFN, Fuelman, Voyager or another fleet card program as well. Star Oil can provide a Pacific Pride or Fuelman card that will work over the road consolidating all your fuel into one bill. Star can also accept Fuelman, Comdata, WEX or Voyager and bill those fleet cards directly with onsite refueling. Call if your fleet uses one of these national fleet cards and you want to move to wet hosing billed directly to the card and license plate of each one of your trucks. (For further reading on corporate fleet card security features please read our article on Upgrade your Fleet Card’s Security Features)

our fleet can pay back rapidly. Even if the majority of your fleet is over the road and out of town, on-site refueling can be a money saving proposition. You can also integrate it seamlessly with a Pacific Pride, CFN, Fuelman, Voyager or another fleet card program as well. Star Oil can provide a Pacific Pride or Fuelman card that will work over the road consolidating all your fuel into one bill. Star can also accept Fuelman, Comdata, WEX or Voyager and bill those fleet cards directly with onsite refueling. Call if your fleet uses one of these national fleet cards and you want to move to wet hosing billed directly to the card and license plate of each one of your trucks. (For further reading on corporate fleet card security features please read our article on Upgrade your Fleet Card’s Security Features)

- If you have a major hub with a critical mass of trucks in town, wet-hosing y

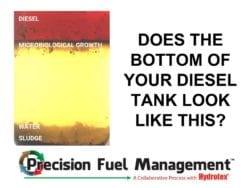

- Cost Plus Diesel – Budget to know every day you are getting a good wholesale rate for your fleet.

- Star Oilco can connect your fleet to an agreed and easily verifiable cost plus supply agreements. Be it OPIS Average or Low Rack Plus agreements we can guarantee you have a good wholesale price of fuel. On-site refueling will provide a simplified fleet management experience for both your drivers and your Accounts Payable department. Call us if you want to talk about what this can do for your business. ( For further reading on the benefits of premium diesel and a wholesale partner for diesel, read our article on What is the benefit of Premium Diesel versus untreated diesel?)

We are here to serve you and keep the process simple. Contact us to learn more at, 503-283-1256.