Backup Generator Fuel

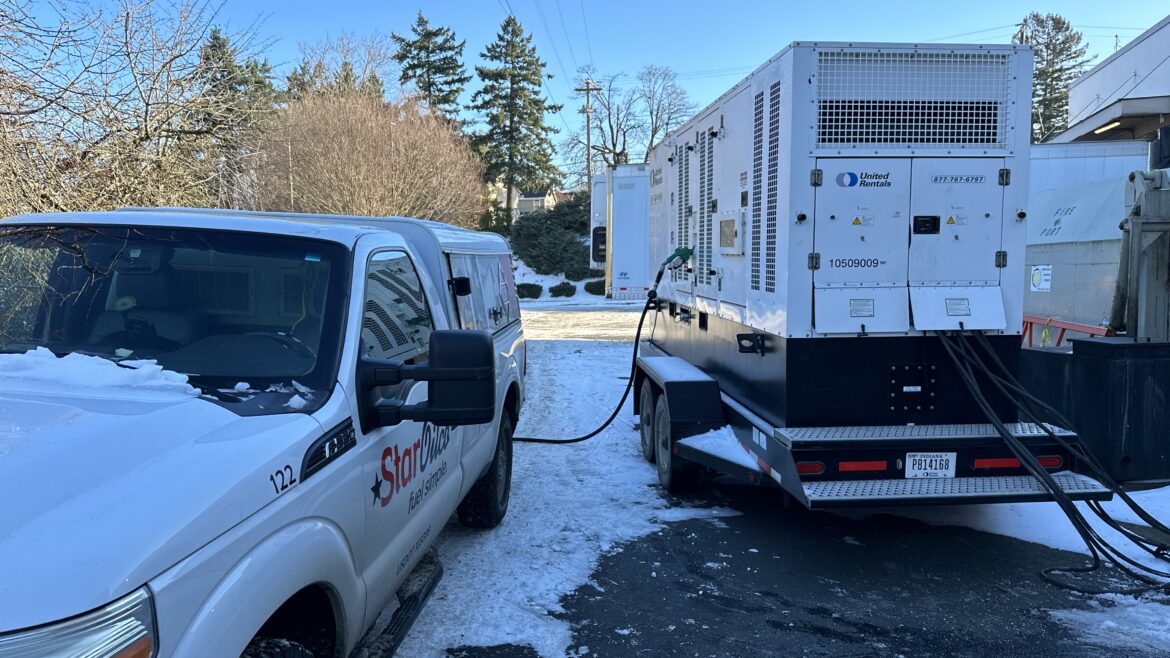

Star Oilco Generator Refueling Service

Make sure your generator fuel tank is filled before the power outage strikes.

Remember that ordering diesel for your generator is a specialized service.

You want to stabilize and treat your diesel for generators and other back up equipment.

Order fuel treated for long term storage!

We often receive questions about backup generators, backup water pumps, and other emergency equipment. Fueling these critical pieces of equipment is a special kind of fueling service but we’re here to answer all your questions.

Generator Fuel is a specially treated oxidative stabalized off-road fuel designed to store for years.

Fuel for a backup generator is a specialized product. Besides the fuel, the service itself takes a vendor who understands your needs and can keep you up and running in an emergency.

Generators take off-road diesel, of course, but you want an ultra low sulfur diesel to ensure it works with modern emission systems. Some companies may deliver a higher sulfur heating oil product that looks the same but can foul the emission systems of your equipment.

Beyond just the service provided by a truck and driver, you also want a vendor who offers a fuel stabilizer and biocide for the special long term storage needs of your backup generator. Star Oilco recommends you add a biocide and long term storage stabilizer to your fuel to ensure it is good whenever you need it. We use Valvtect Bioguard Plus 6 for generators, emergency water pumps, backup boiler fuel, and other long term storage purposes. This product kills any existing biological growth and stabilizes your fresh diesel fuel for long term storage. Make sure your diesel is ready the next time you need backup power.

As a complimentary service to our customers, Star Oilco will also test fuel for its quality. If you want to confirm fuel quality at the time of a top off, let us know and we will ensure the driver has a sample kit to get your backup fuel tested for peace of mind.

Feel free to message us if you need a backup tank filled. If you are in charge of Corporate Fueling, please call with any questions you may have.

Read more about stabilizing your generator fuel for long term storage.

Keep it simple with Star Oilco. We make it easy for you to be prepared.

Is off-road diesel or dyed diesel high sulfur diesel?

Is off-road diesel or dyed diesel high sulfur diesel?