What Types of Feedstock Can Be Used To Make Biodiesel?

To answer what feedstocks can be used to make biodiesel we need to first answer – What is Biodiesel?

Biodiesel is created through a process called transesterification. Transecterification is when an alcohol such as methanol or ethanol is added to an oil or fat. This creates methyl esters and glycerin. Methyl esters is the scientific name of Biodiesel. Because biodiesel needs a fat or an oil to start with, this fuel can can be created with any number of feedstocks. If you would like to learn more about Biodiesel check out this for more questions about biodiesel.

According to the U.S. Office of Energy Efficiency & Renewable Energy:

“A feedstock is defined as any renewable, biological material that can be used directly as a fuel, or converted to another form of fuel or energy product. Biomass feedstocks are the plant and algal materials used to derive fuels like ethanol, butanol, biodiesel, and other hydrocarbon fuels. Examples of biomass feedstocks include corn starch, sugarcane juice, crop residues such as corn stover and sugarcane bagasse, purpose-grown grass crops, and woody plants. “

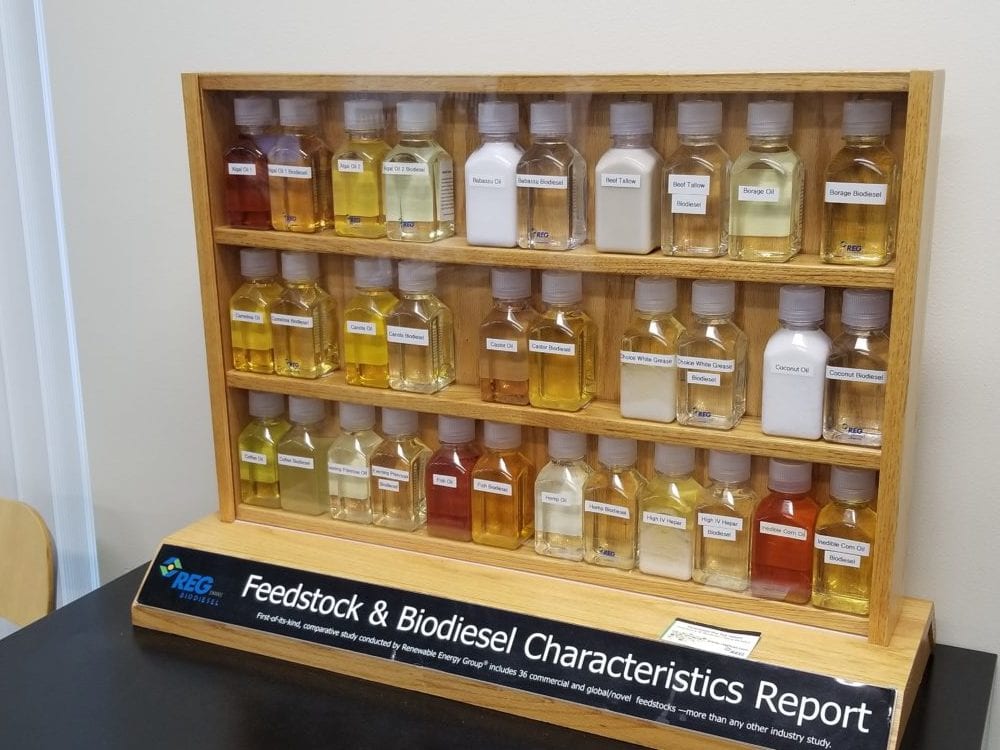

Renewable Energy Group (REG) performed a study in 2009 with the support of the Iowa Power Fund Board and the Iowa Office of Energy Independence that tested 36 individual feed-stocks. Star Oilco will be spotlighting these feedstocks through our blog and our social media. The full report can be found on their site if you would like to read ahead or explore the results in more depth. We hope you find these as interesting as we did!

Above photo taken at REG headquarters in Ames, Iowa.

This first blog highlights the following 2 types of feed-stock:

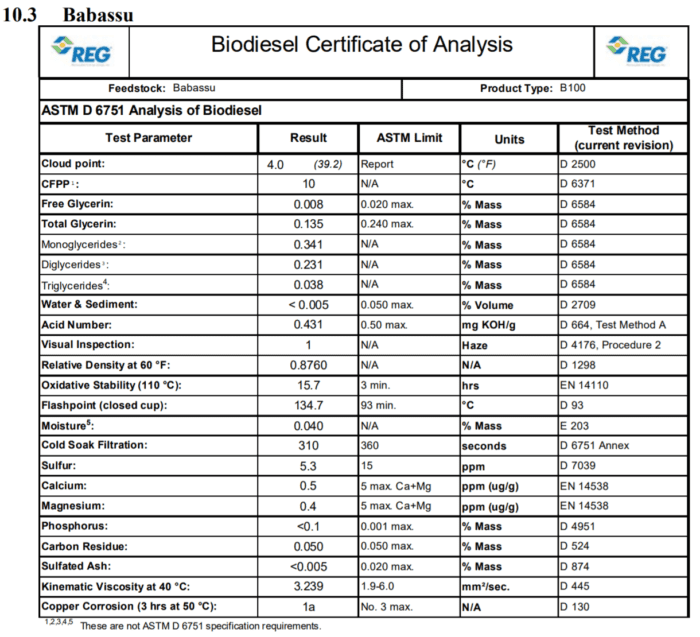

Babussa Oil & Beef Tallow

Babassu Oil

Babassu oil is extracted from the seeds of the babassu palm tree, Attalea speciosa, an evergreen tree growing to 30 m (98ft) by 20 m (65ft) at a slow rate. It is hardy to zone (UK) 10 and is not frost tender. The flowers are pollinated by bees and other insects. The tree is common in Brazil, Mexico, and Honduras; it grows well in areas typically cultivated for coconut or palm. The kernels contain 60-70% oil, appear transparent, and smell like walnuts. In its natural form the oil is liquid at 20-30°C (68 – 86°F). The seeds are edible and the oil is used in margarine, soaps, detergents, lamp oil and skin products. Oil extraction results in a cake containing 15-25% protein (depending on the shell content), which is a valuable feedstuff.

In February 2008, Babassu palm oil and coconut oil were blended with jet fuel to power a Virgin Atlantic Boeing 747 during a test flight from London’s Heathrow to Amsterdam.

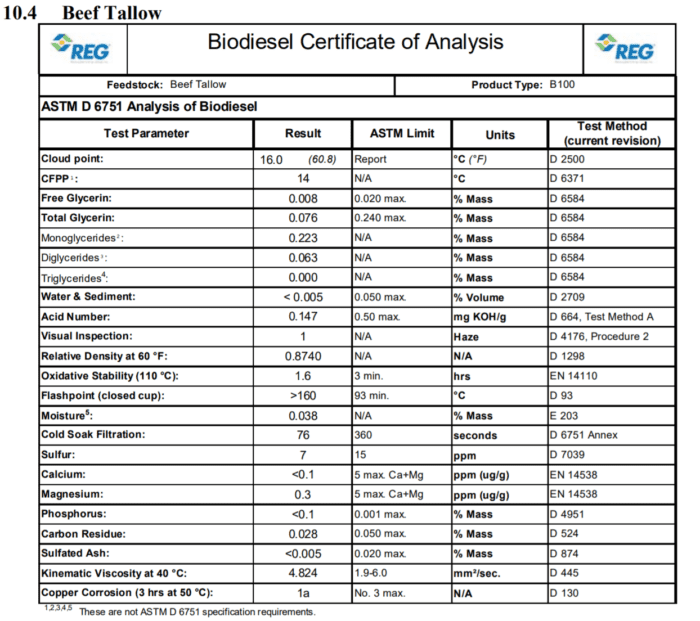

Beef Tallow

Tallow is a rendered form of the waste fats and greases from processing beef. Rendering is a process by which lipid material is separated from meat tissue and water under heat and pressure. Beef tallow is primarily made up of triglycerides and it is solid at room temperature. The B100 that is created from this source has a very high cloud point. “Cloud point is the temperature at which wax (paraffin) begins to separate when oil chilled to a low temperature, and it serves as an important indicator of practical performance in automotive applications in low temperatures.” (Source) The other uses for tallow include animal feed, soap, cooking and in the past, candles.

Oregon law has a 5% Biodiesel and 10% Ethanol fuel blend mandate.

Oregon law has a 5% Biodiesel and 10% Ethanol fuel blend mandate.