Easy Construction Jobsite Fueling

Diesel Fueling for Construction Projects in Oregon

Get a Star Oilco account and make your jobsite fueling easy.

Star Oilco is on the road fueling construction, jobsites and generators.

Star Oilco is here to serve your diesel fueling needs.

Fueling in the Portland, Oregon and Vancouver, Washington service areas.

We are now Serving Salem, OR and Surrounding areas.

Regardless if your project is for one day or a few years, we are here to keep that equipment topped off and running. Star Oilco does wet hose fueling construction jobsites in Vancouver, Washington and Portland, Oregon. We have also expanded in the Salem, Oregon and the surrounding areas with fleet fueling and On-site fueling. Our dyed diesel, clear diesel, or gas construction refuelers are on the road ready for your order.

We fill your equipment with diesel and we can deliver DEF as well.

Whether it’s backhoes and loaders or lightsets, generators, refrigerated trailers, and pumping equipment. Star Oilco is there with regular on-time, off-road diesel fuel in the Portland and Vancouver markets. If you have a need for gasoline in small volumes on your site, we can help with that as well. If you need fuel and want it there on time, we are here to keep you up and running. We keep your equipment full so you can focus on the project.

We loan diesel and gasoline tanks to simplify your project fueling needs.

Loaner tanks are also immediately available for your project to keep fuel costs down. Avoid the recurring rental costs and go with a vendor who truly cares about your up time and schedule needs. Whether it is high service hands on wet hosing fueling or bulk drops, Star Oilco makes fueling your construction project easy.

Save money, time and labor with a better construction fueling partner.

Sending your scarce and expensive human resources to gas stations to pay retail prices for diesel eats up far more money than you think. Make fueling your project an afterthought and keep the equipment making you money moving. Star Oilco is here to make your project management easier. Keep your equipment moving and on the job and kick those fuel cans.

Let us know if we can be of help. We keep it full!

On-Site Fueling and Fleet Cards: Combine your construction fueling with Pacific Pride fuel cards to improve your operational efficiency as well as save on your cost of fuel. Get away from those credit card fees while increasing your security from fuel theft with Star Oilco.

How to use secure gas cards to protect your business from fuel theft: Star Oilco can also pair your construction fueling account with a Pacific Pride card. We approach Commercial Cardlock and Fleet Cards differently. With an easy to implement system to ensure you are not seeing fuel theft.

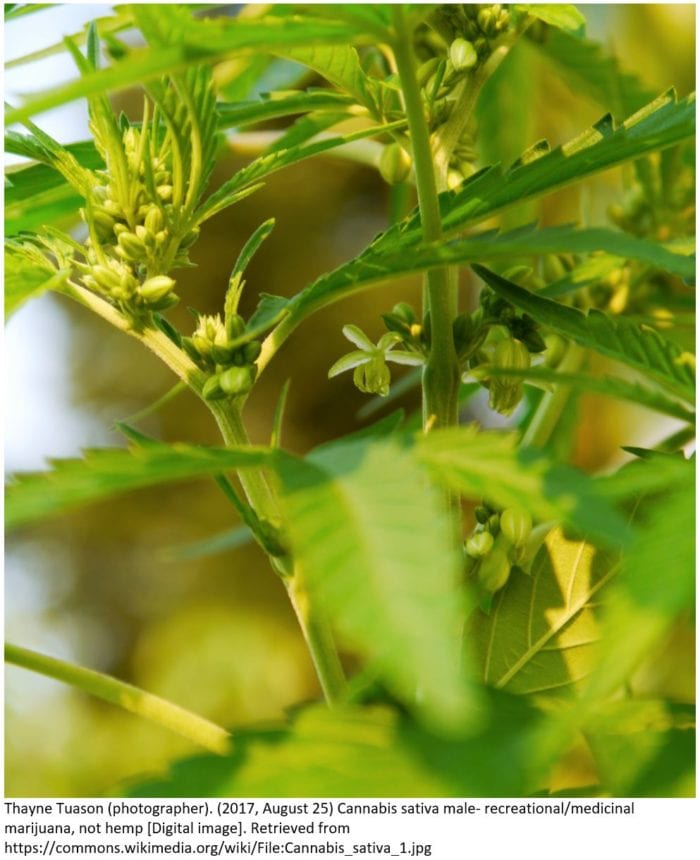

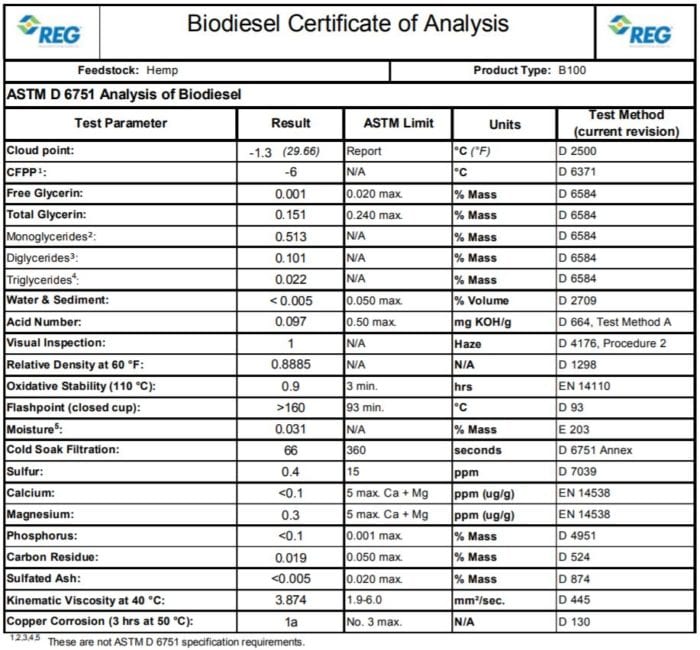

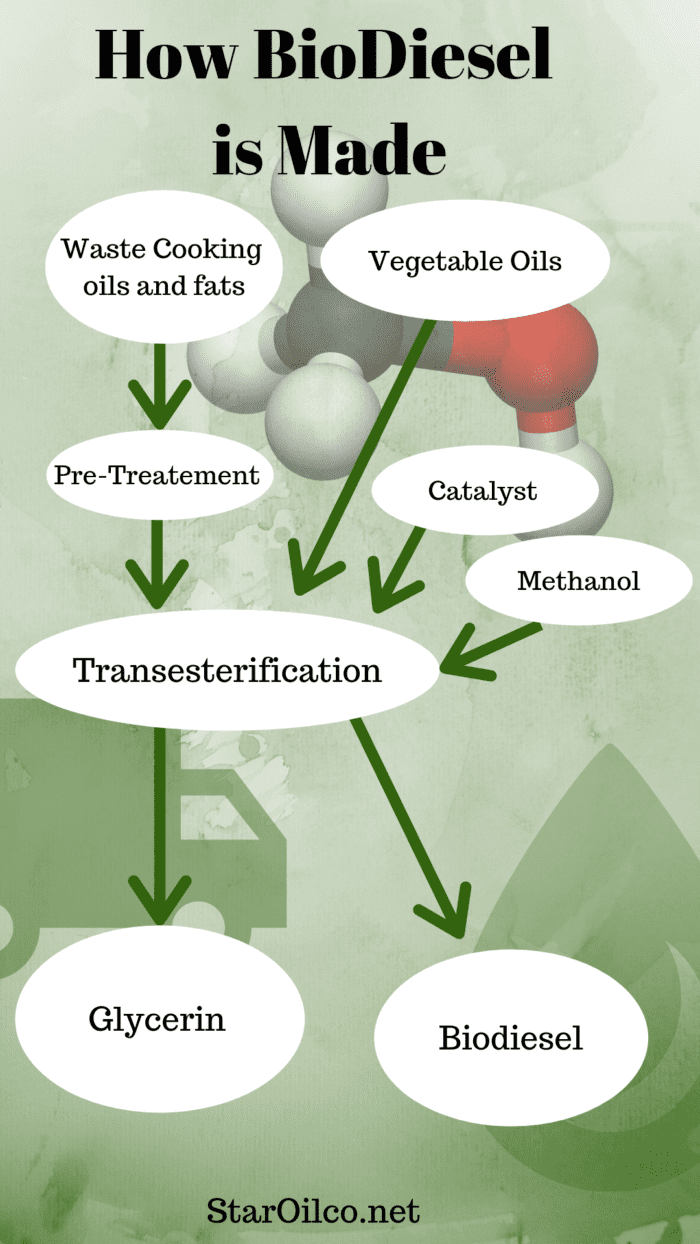

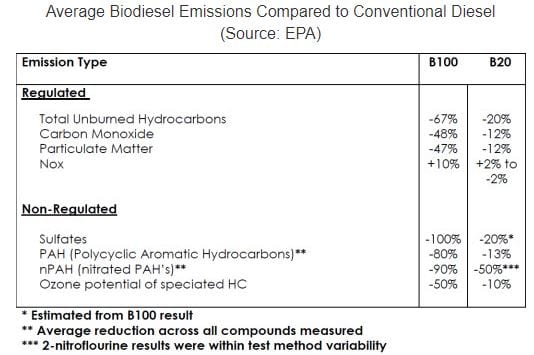

When you use biodiesel, you’re using CO2 that is being captured by the growing plants or the waste. This is current CO2 you aren’t adding to the net sum in the environment.

When you use biodiesel, you’re using CO2 that is being captured by the growing plants or the waste. This is current CO2 you aren’t adding to the net sum in the environment.

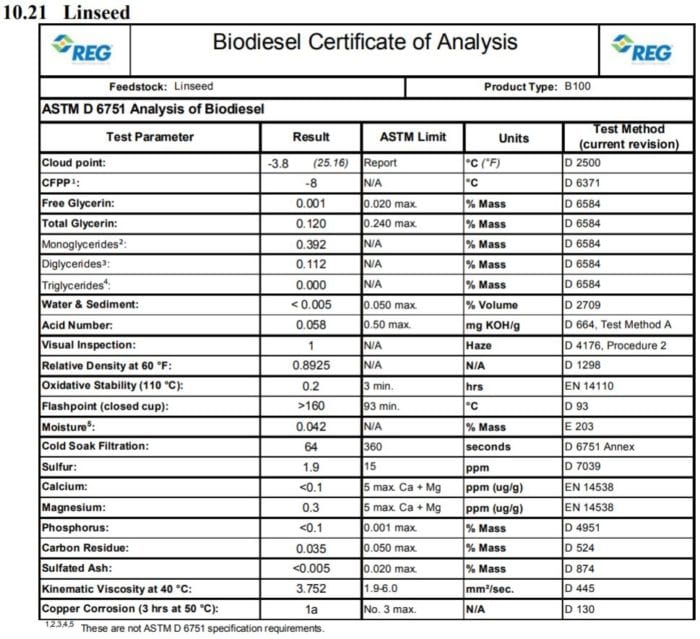

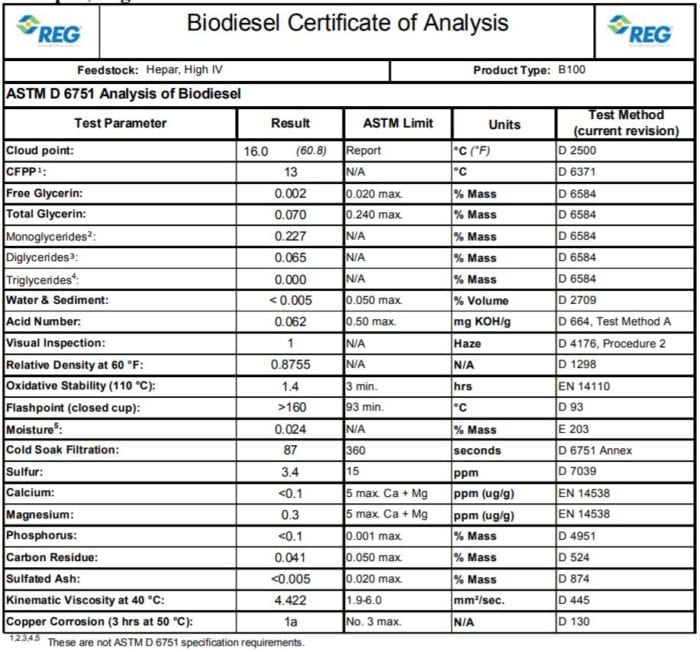

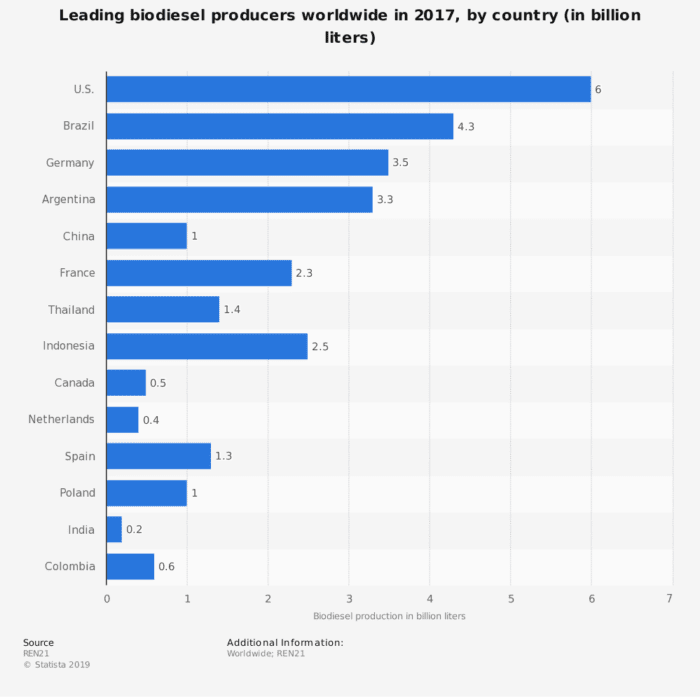

For example, it grows in Argentina, India, and Canada. Linseed oil has been traditionally used as a drying oil. According to

For example, it grows in Argentina, India, and Canada. Linseed oil has been traditionally used as a drying oil. According to