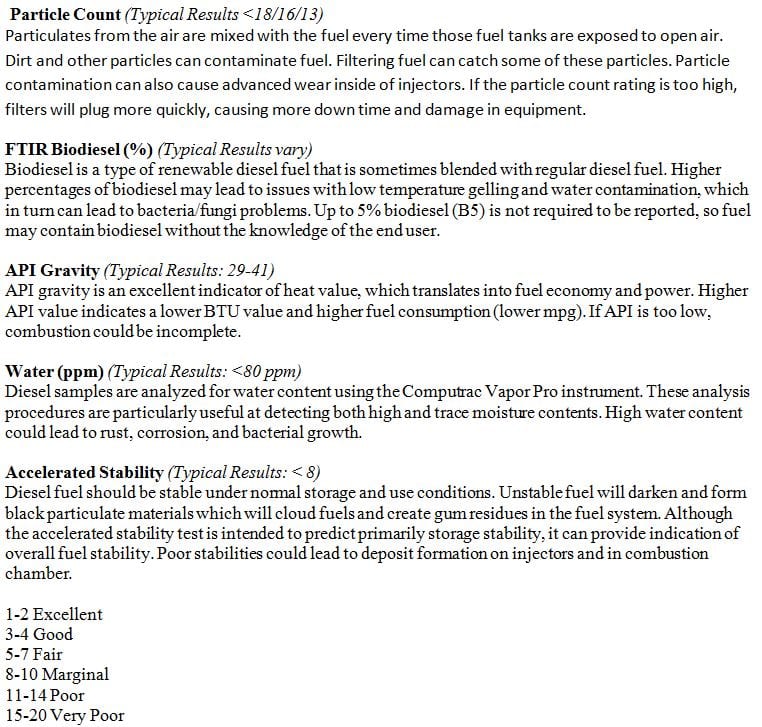

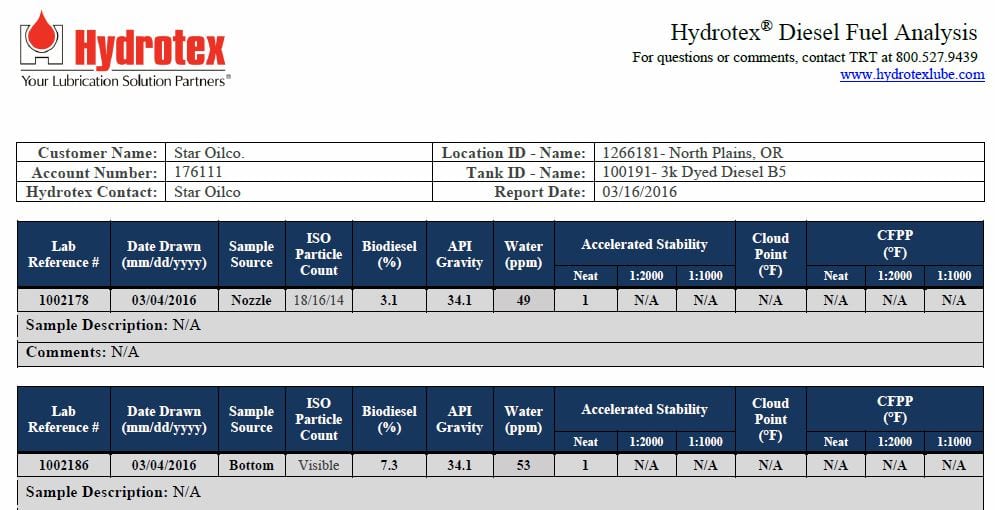

First sample taken 09-18-2015, lots of water and visible dirt in samples pulled from bulk tank. The company was having issues with equipment running rough, and they were spinning fuel filters way more than manufacturers recommended changes. We sat down with the plant supervisor and talked about diesel fuel quality testing. He was happy to hear his diesel fuel problems explained. It has nothing to do with diesel fuel quality by brand. All fuel vendors get the same fuel supplied to the Northwest. The environment where this client is located has dust, dirt, and water in the air constantly due to the nature of the recycling processes with wood products. Our first goal was to sample the tank bottom and nozzle and share the results. As you can see from above, they had tons of water and dirt in the tank. So we set up to clean the bulk tank, polish the fuel with 1 micron filtration, then install quality Donaldson clean & dry filtration including a 4 micron particulate filter, a water filter, and a desiccant breather trap to control the moisture that accumulates in most all bulk tanks. The client had dirty diesel fuel filters that were only 30 micron, letting all the damaging particles right into the equipment.

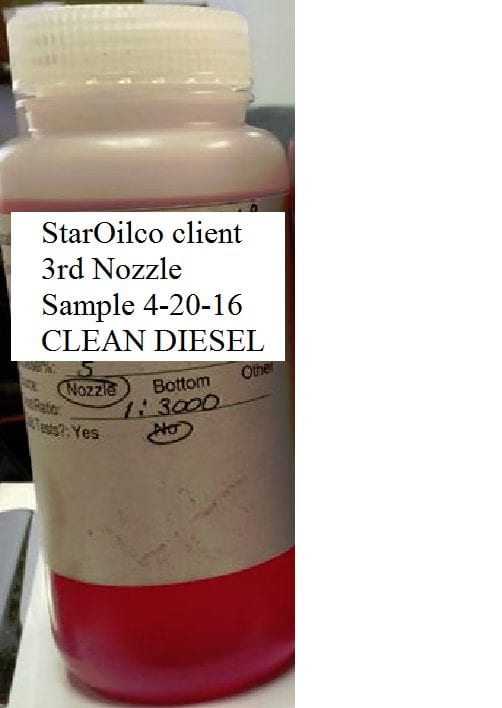

COMPARE THE VISUAL AND DATA IMPROVEMENTS

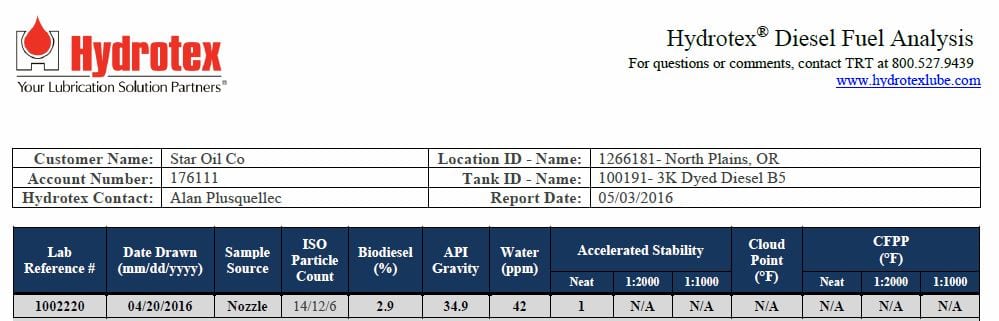

The second round of samples after the tank was initially cleaned, and the remaining fuel was polished with 1 micron filtration. The process is showing signs of improvement after cleaning the tank. The Donaldson Filtration and Hydrotex PowerKleen additive was working on the contents of the tank, and the inside of the tank is being cleaned by the additive. The effects of water that was in the tank, and rust and corrosion showed signs of improvement on the second samples. Both water and rust will continue to be less in volume each time we sample, it is a continuous improvement program. Over time the water and rust goes away or is caught by the excellent Donaldson Clean & Dry filtration and what remains is attacked by the superior quality of Hydrotex PowerKleen additive!

The most damaging particles and water, the ones between 4 and 8 microns,

are being filtered out of the fuel, the one’s we can’t see with the naked eye.

After only 3 months on the Precision fuel management program the ISO count is well below the manufacturers specs for ANY of the customers equipment. The water PPM (Parts per million) is now 42 down from 89, well below ASTM standards. THESE NUMBERS DON’T LIE, THE PROGRAM WORKS! To maintain this quality consistently the client only needs to change the filtration when the filtration gauges jump 10 PSI over normal flow rate. The Desiccant breather which controls moisture, has an indicator that turns RED from it’s original YELLOW to let you know it’s time to change. The Hydrotex additive will continue to make the water drop out of the fuel, keep cleaning the rust and corrosion in the tank, and help with lubricity for the equipment that fuels from the tank.

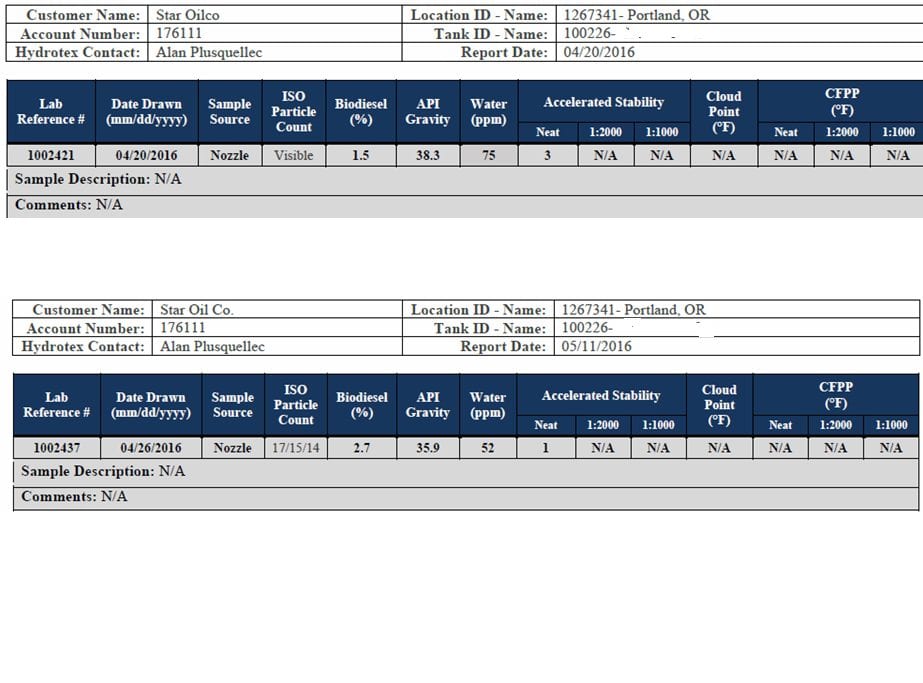

Another customer of ours was having issues with their previous fuel vendor, I approached the operations manager and let him know that we had a program that could turn their fuel issues around. He agreed to let me take bottom and nozzle samples from his tank, the results came back un-readable, meaning there was so much dirt and water that you could see it with the naked eye, (not good). All the damaging particles are between 2 and 8 microns. If you can see visible particles and water you know you are in trouble. We recommended our Precision fuel management program including cleaning the tank and using Donaldson Clean & Dry filtration along with Hydrotex PowerKleen additive and our Star Oilco Premium filtered diesel. Within 3 weeks the client saw results.

“The latest nozzle sample is looking very good, will continue to get down around 14/13/11”. In just one week after the second sample the water ppm has dropped to 52, which is well below the goal of 80 ppm. It dropped 20ppm after only one week of Hydrotex PowerKleen additive making the water drop out of the fuel.

The API gravity is down to 35.9, which means more BTU’s (heat transfer) meaning better gas mileage and horsepower. The fuel is burning clean and dry, like it is supposed to.

The client said, “We have not been spinning filters as often as we were in the past, we see an overall improvement in fuel quality since starting the Precision fuel program with Star Oilco.” Look at the before and after data below from the lab

Another satisfied Star Oilco Precision fuel management program customer!

If you suspect you have fuel issues because you’re seeing:

- Fuel filters plugging

- Trucks and equipment are running rough

- Poor engine performance and fuel mileage below normal

- Fuel injector issues, pitting scaring or blown out tips

You may have issues with your bulk tank and filtration on the tank.

We can help you with a complementary lab sample test like you see above.

RULE OUT FUEL QUALITY AND BULK TANK FILTRATION ISSUES