Renewable Diesel vs Biodiesel

What’s the difference and how do they compare in price?

If you are looking for a cleaner and greener alternative to diesel fuel, you might have come across two options: renewable diesel and biodiesel. Both fuels are made from organic sources, such as vegetable oils and animal fats, but they have different production processes and properties. In this blog post, we will compare renewable diesel and biodiesel in terms of their pros and cons, as well as their prices and incentives in Oregon.

What is Renewable Diesel?

Renewable diesel is a fuel that is chemically identical to petroleum diesel, but it is made from renewable raw materials through a process called hydrotreating. Hydrotreating removes impurities and oxygen from the feedstock, resulting in a pure and refined fuel that can be used in any diesel engine without modifications or blending. Renewable diesel (R99) has a high cetane number, which means it ignites easily and burns efficiently. It also has a low cloud point, which means it can withstand cold temperatures without gelling or clogging filters.

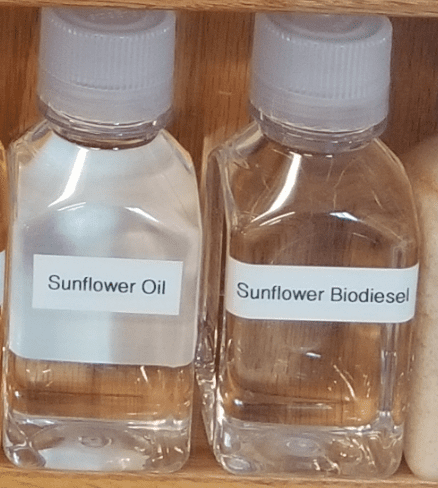

What is Biodiesel?

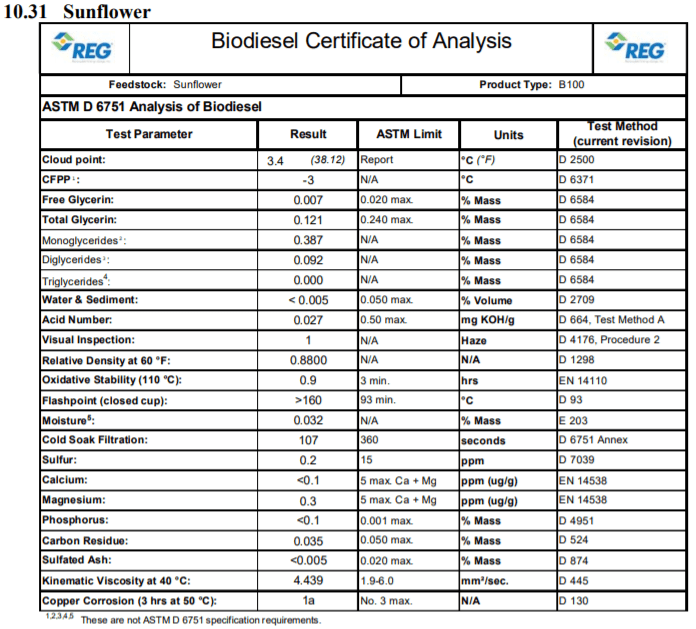

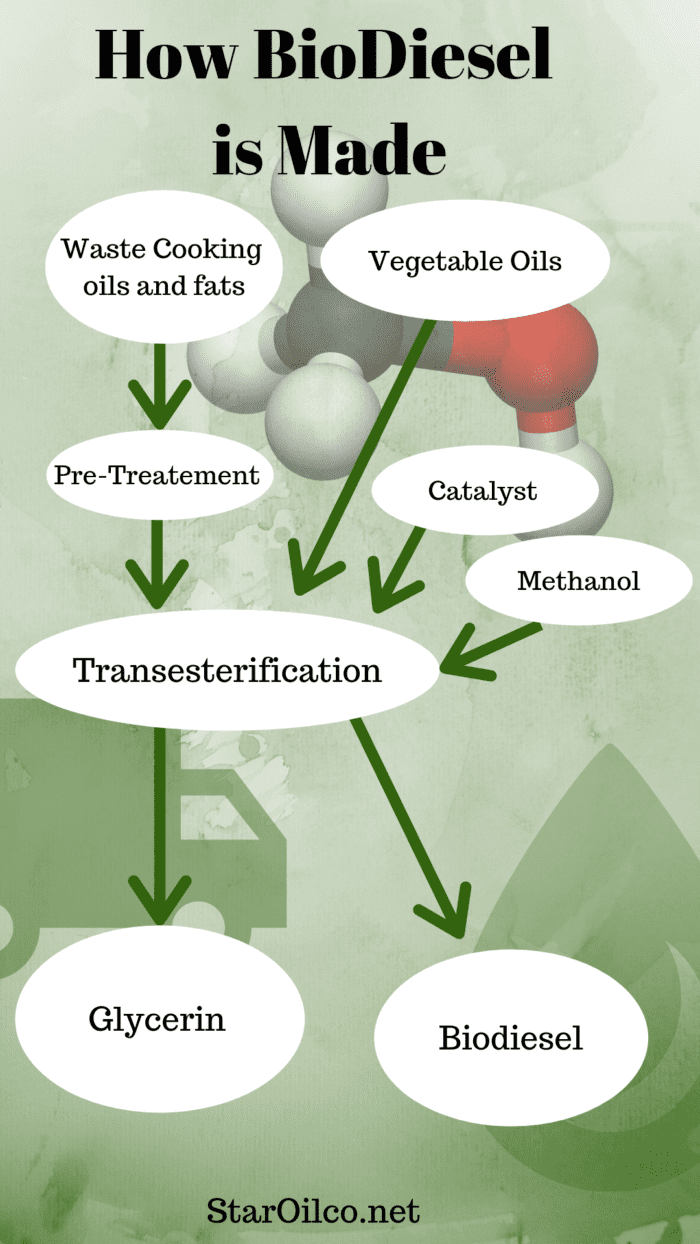

Biodiesel is a fuel that is made from renewable raw materials through a process called transesterification. Transesterification converts the feedstock into fatty acid methyl esters (FAME), which are then blended with petroleum diesel at various ratios. Biodiesel can be used in most diesel engines, but it may require some modifications or adjustments depending on the blend level and the engine type. Biodiesel has a lower cetane number than renewable diesel, which means it may not ignite or burn as well. It also has a higher cloud point than renewable diesel, which means it may gel or clog filters in cold weather.

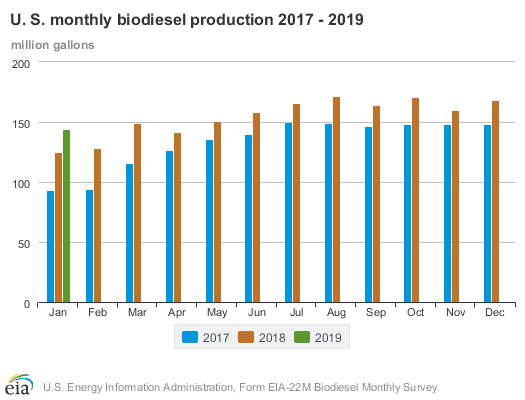

The cost of renewable diesel and biodiesel depends on various factors, such as the type and availability of feedstock, the production process, the market demand, and the government incentives. In general, renewable diesel is more expensive than biodiesel, as it requires more complex processing and higher quality feedstock. According to the U.S. Energy Information Administration (EIA), the average wholesale price of renewable diesel in California was $3.06 per gallon in October 2021, while the average wholesale price of biodiesel was $2.76 per gallon in the same month. However, both renewable diesel and biodiesel can benefit from federal RIN’s and state credits such as the low carbon fuel standards, which can lower their effective prices and make them more competitive with petroleum diesel. As of July 10th of 2023 renewable diesel (R99) in Portland Oregon was 60 cents higher than biodiesel (B99).

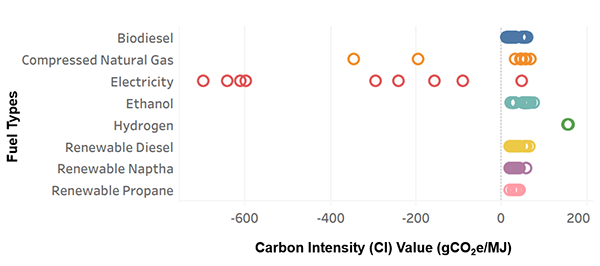

Renewable Diesel vs Biodiesel Carbon Intensity

According to CARB, the carbon intensity of biodiesel ranges from 14.85 to 67.45 gCO2e/MJ and, renewable diesel ranges from 15.84 to 62.86 gCO2e/MJ, depending on the feedstock and production pathway. The lowest carbon intensity for biodiesel is achieved by using waste cooking oil as the feedstock and renewable methanol as the transesterification agent. The highest carbon intensity is associated with using soybean oil as the feedstock and fossil-based methanol as the transesterification agent. The lowest carbon intensity for renewable diesel is achieved by using waste cooking oil as the feedstock and renewable hydrogen as the hydrotreating agent. The highest carbon intensity is associated with using soybean oil as the feedstock and fossil-based hydrogen as the hydrotreating agent.

Pros and Cons of Renewable Diesel and Biodiesel

Both renewable diesel and biodiesel have some advantages and disadvantages compared to petroleum diesel. Here are some of the main pros and cons of each fuel:

Renewable Diesel Pros:

– Reduces greenhouse gas emissions by up to 75% compared to petroleum diesel

– Reduces tailpipe emissions of particulate matter, nitrogen oxides, carbon monoxide, and hydrocarbons

– Improves engine performance and efficiency with fewer regeneration cycles of the emissions system

– Compatible with existing infrastructure and vehicles

– Biodegradable and nontoxic

Renewable Diesel Cons:

– More expensive than petroleum diesel

– Limited availability and supply

– May increase emissions of sulfur dioxide

Biodiesel Pros:

– Reduces greenhouse gas emissions by up to 78% compared to petroleum diesel

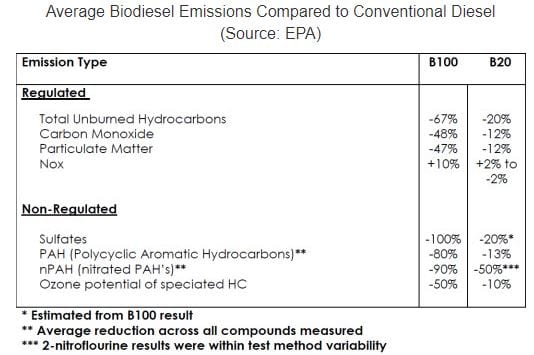

– Reduces tailpipe emissions of particulate matter, carbon monoxide, and hydrocarbons

– Biodegradable and nontoxic

– Supports domestic agriculture and energy security

Biodiesel Cons:

– May increase emissions of nitrogen oxides

– May cause engine problems such as injector coking, filter plugging, corrosion, and reduced lubricity

– May degrade over time or when exposed to water or microbes

Oregon Prices and Incentives for Renewable Diesel and Biodiesel

Oregon is one of the states that has adopted a Clean Fuels Program (CFP), which aims to reduce the carbon intensity of transportation fuels by 10% by 2025. The CFP creates a market for low-carbon fuels such as renewable diesel and biodiesel by requiring fuel suppliers to either blend them with petroleum diesel or buy credits from low-carbon fuel producers. The CFP also provides incentives for consumers to use low-carbon fuels by reducing their fuel taxes.

According to the Oregon Department of Environmental Quality (DEQ), the average price of diesel in Oregon as of November 2021 was $3.87 per gallon. The average price of biodiesel blends ranged from $3.88 per gallon for B5 (5% biodiesel) to $4.01 per gallon for B20 (20% biodiesel). The average price of renewable diesel was $4.05 per gallon. As of July 2023 the price of renewable diesel (R99) in Oregon was 50 to 60 cents higher than biodiesel (B99).

The DEQ also provides a Fuel Cost Calculator that allows consumers to compare the costs and benefits of different fuels based on their vehicle type, fuel efficiency, annual mileage, fuel price, carbon intensity, and tax rate. According to the calculator, using renewable diesel instead of petroleum diesel would save an average consumer $34 per year in fuel costs and reduce their carbon emissions by 1.6 metric tons per year. Using biodiesel instead of petroleum diesel would save an average consumer $12 per year in fuel costs and reduce their carbon emissions by 0.8 metric tons per year.

Renewable diesel and biodiesel are both viable alternatives to petroleum diesel that can help reduce greenhouse gas emissions and support renewable energy sources. However, they also have some trade-offs in terms of cost, availability, performance, and emissions. Consumers should consider their vehicle type, driving habits, fuel preferences, and environmental goals when choosing between these fuels. Oregon offers some incentives and programs to encourage the use of low-carbon fuels such as renewable diesel and biodiesel, which can help consumers save money and reduce their carbon footprint.

When you use biodiesel, you’re using CO2 that is being captured by the growing plants or the waste. This is current CO2 you aren’t adding to the net sum in the environment.

When you use biodiesel, you’re using CO2 that is being captured by the growing plants or the waste. This is current CO2 you aren’t adding to the net sum in the environment.