Fuel Market Report: Oct 6th – Oct 12th, 2024

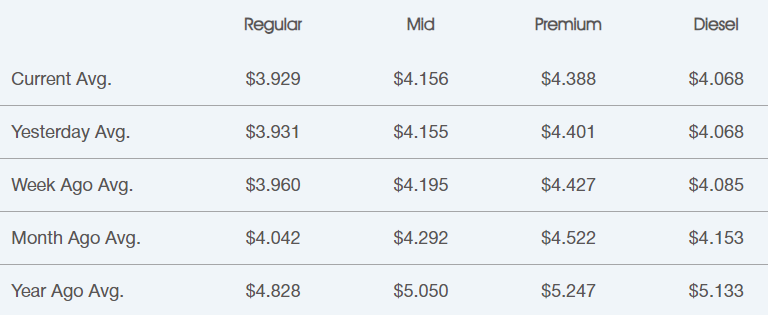

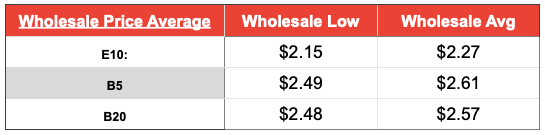

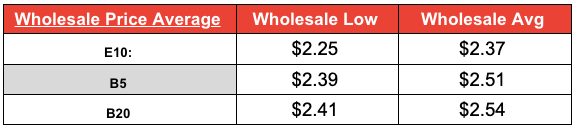

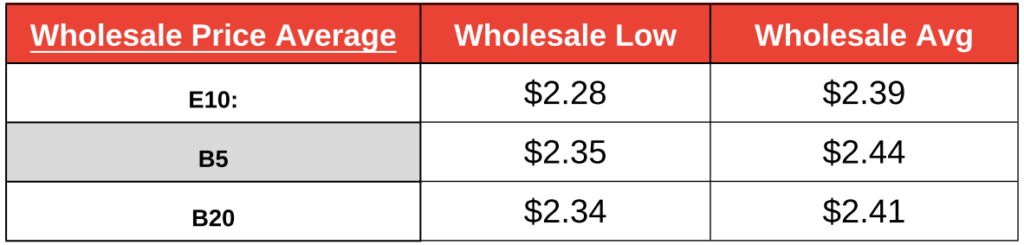

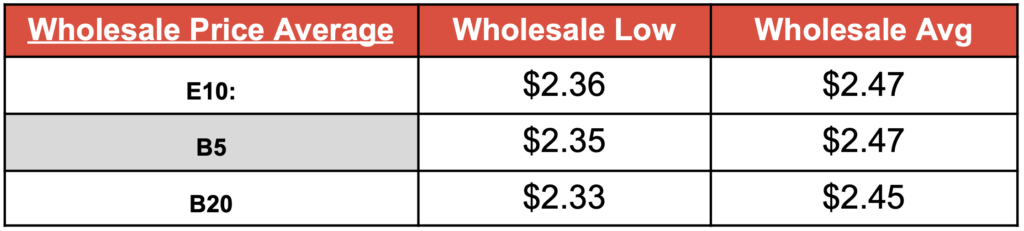

Wholesale Price Average 10/12/24

| Wholesale Low | Wholesale Avg | |

|---|---|---|

| E10 | $2.21 | $2.39 |

| B5 | $2.57 | $2.73 |

| B20 | $2.58 | $2.70 |

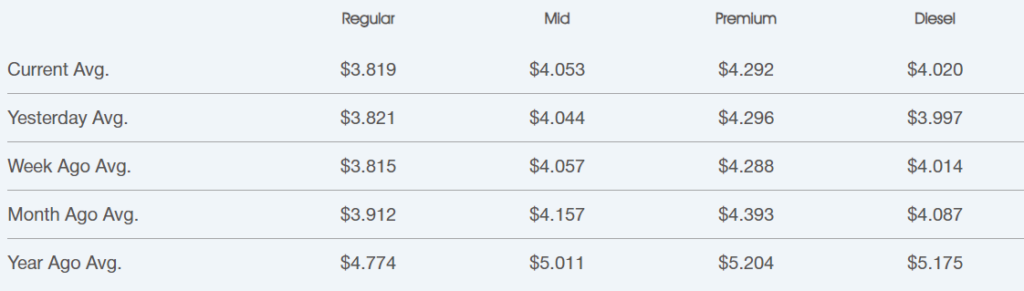

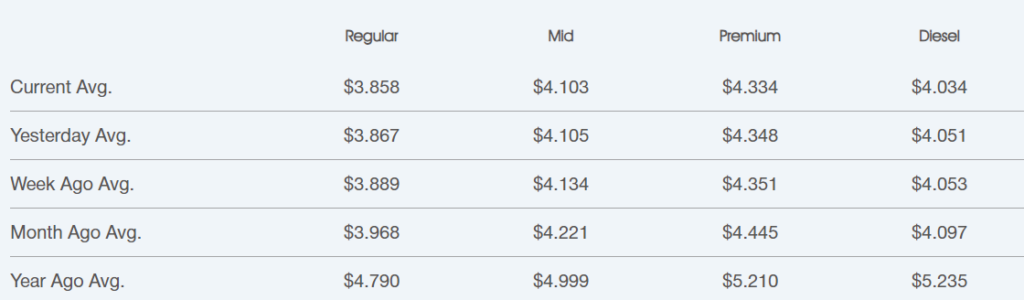

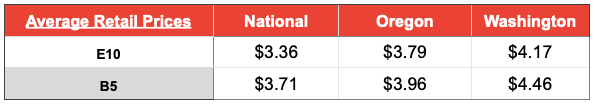

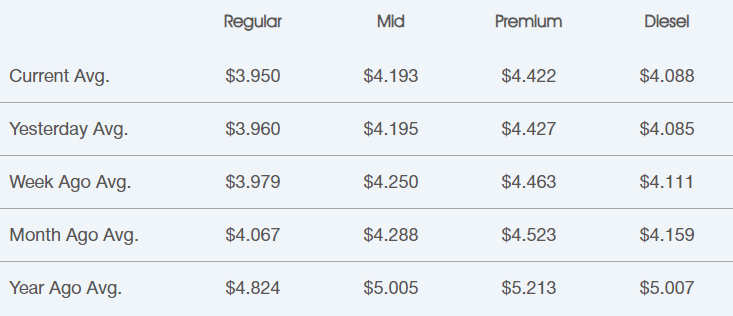

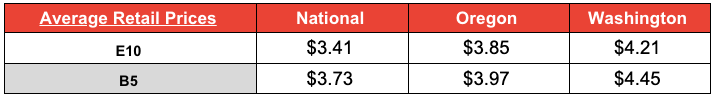

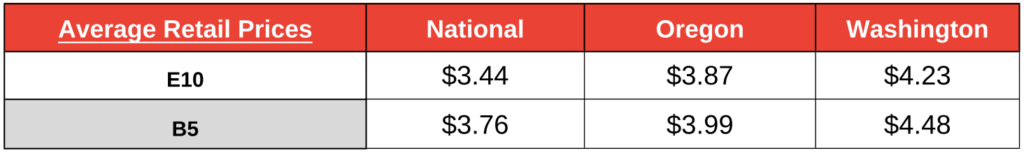

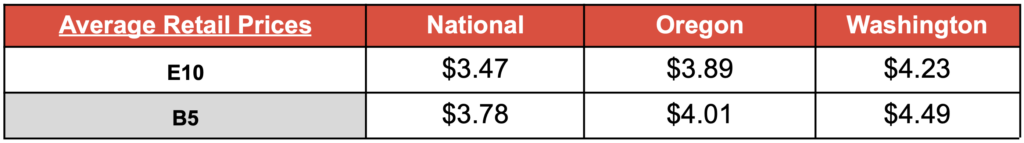

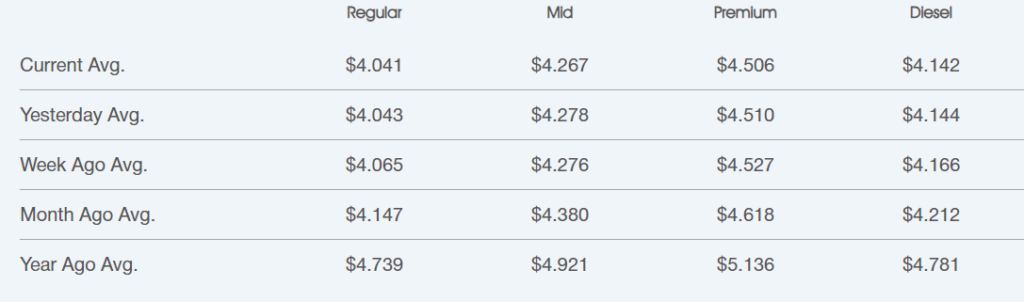

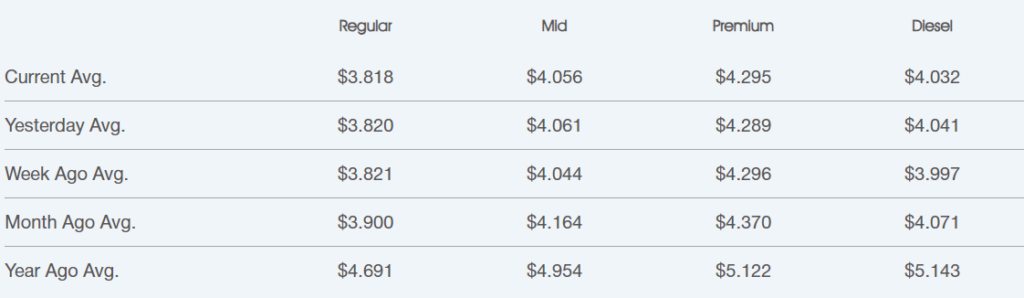

Average Retail Prices 10/12/24

| National | Oregon | Washington | |

|---|---|---|---|

| E10 | $3.20 | $3.67 | $4.07 |

| B5 | $3.60 | $3.94 | $4.38 |

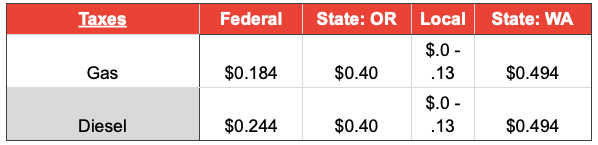

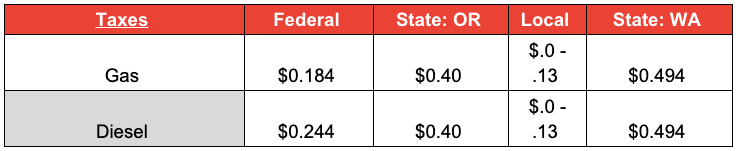

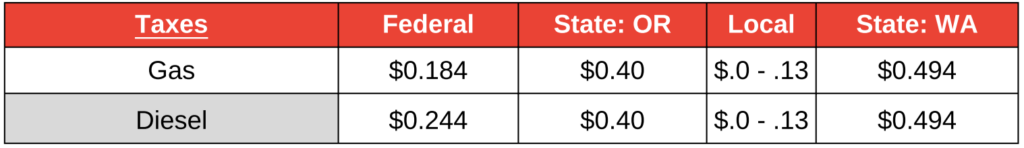

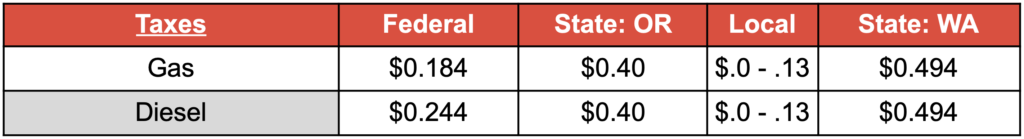

Taxes

| Federal | State: OR | Local | State: WA | |

|---|---|---|---|---|

| Gas | $0.184 | $0.40 | $0-.13 | $0.494 |

| Diesel | $0.244 | $0.40 | $0-.13 | $0.494 |

Oregon Fuel Price Variance

Fuel Market News

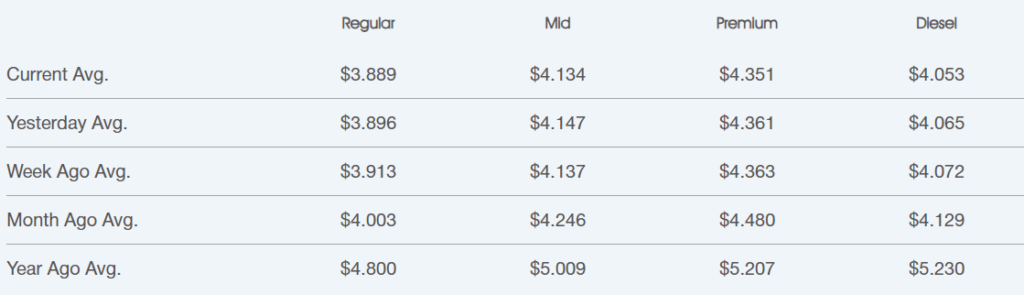

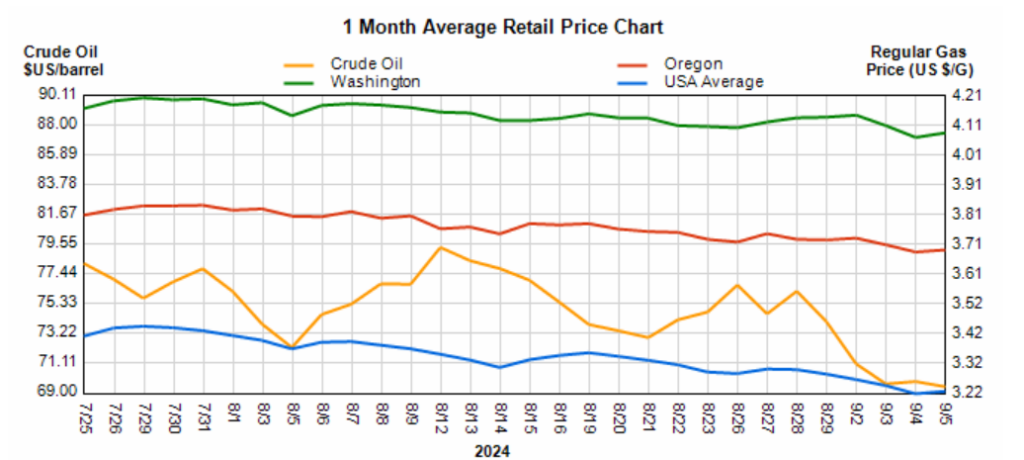

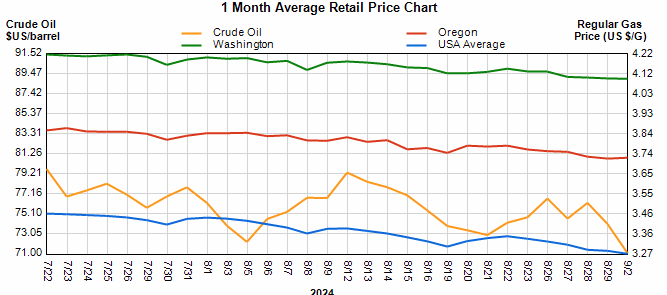

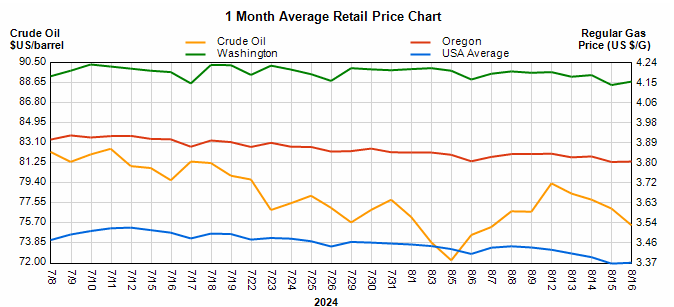

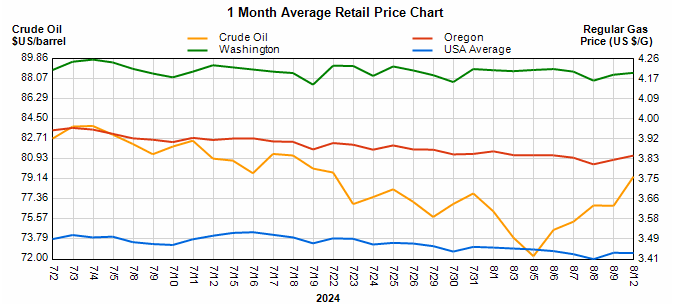

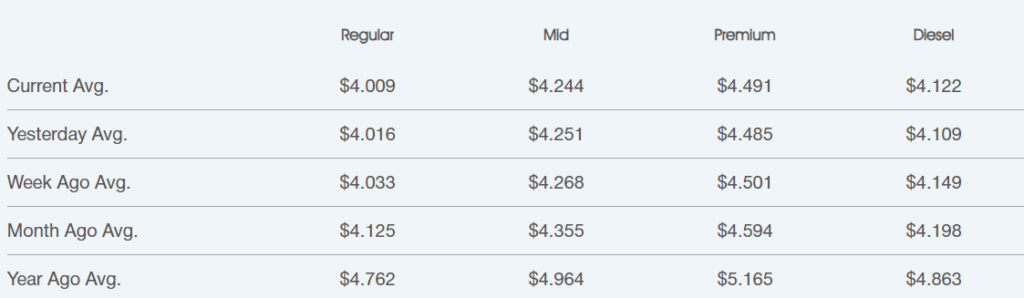

Prices jumped again this past week with rack averages up on all products. Most of this influx was seen within the wholesale market and had little impact on prices on the retail side of the market. Rack averages for E10 jumped $0.11/gal while B5 & B20 both jumped over $0.20/gal. The retail average in Oregon only moved $0.01/gal for gas and $0.13/gal. Most Oregon stations have switched to the winter blend of fuel, which should help prices trickle back down in the coming weeks. The logistical challenges and refinery switches required for this new fuel may have contributed to the uptick in prices in recent weeks.

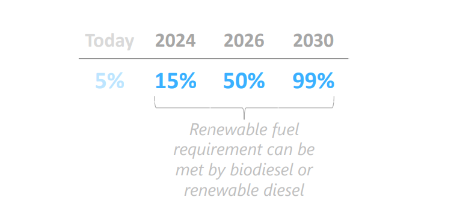

Important Note: Per the City Of Portland, “Distributors in the City of Portland are required to meet the minimum biofuel content requirements for all fuel they distribute beginning on May 15, 2024. All diesel fuel distributed to retail stations, non-retail dealers, or wholesale purchaser-consumers must include a minimum of 15% biofuel content, from either renewable diesel or biodiesel. This requirement increases to 50% on May 15, 2026, and 99% on May 15, 2030”.

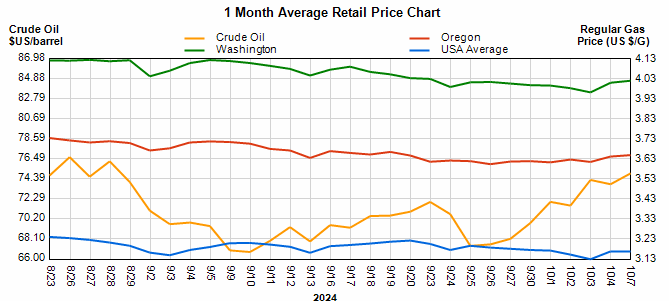

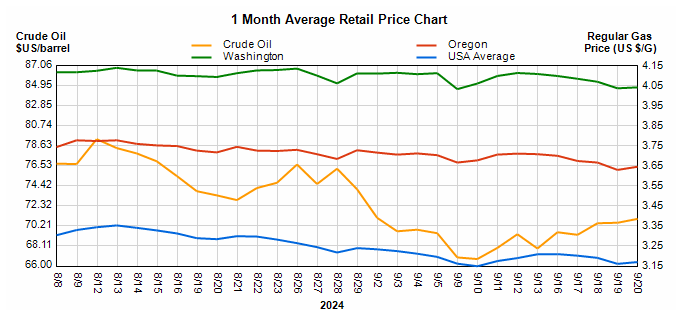

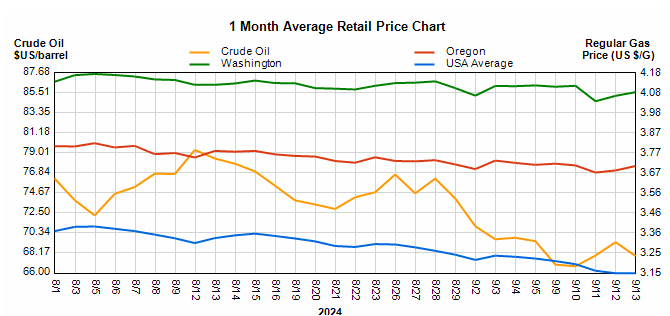

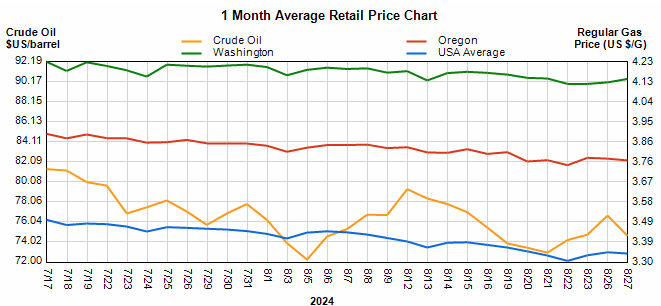

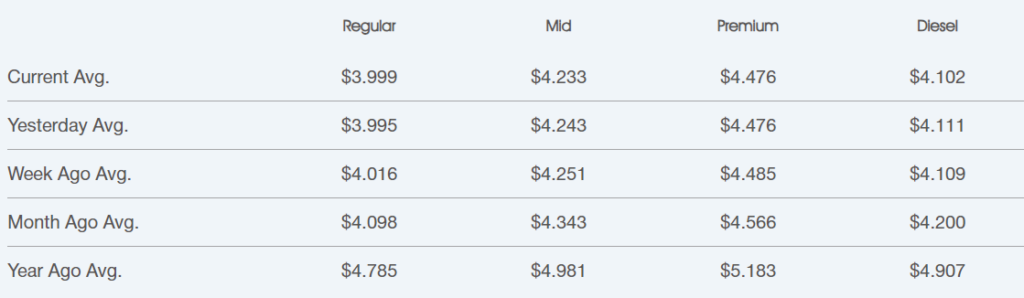

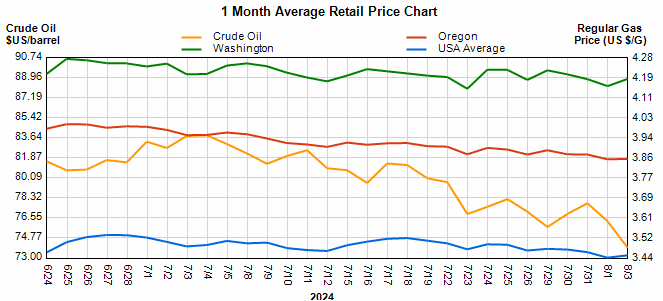

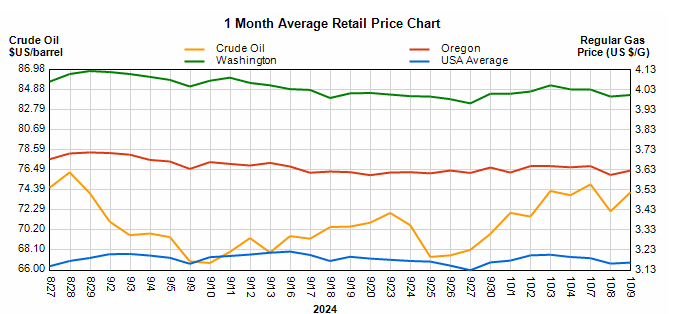

Crude oil is trading below $75 this past week, at a current price of $74.11/barrel. This is $0.45 higher than it was last week. Despite the rise, oil prices are still relatively low. With increased concerns of war in the Middle East, many fear oil prices may be bound to jump at any time but this has yet to happen.

Crude oil is the main ingredient for gasoline and diesel. Per AAA, on average about 50% of what you pay at the pump is the price of crude oil, breaking down as 25% refining, 11% distribution & marketing, and 14% taxes—a helpful breakdown for consumers wondering why they are paying the prices that they pay. Crude Oil is trading at $74.11/barrel compared to $73.66/barrel, last week and $81 a year ago.

It’s essential to recognize that fuel prices result from a complex interplay of the factors mentioned above and other factors regionally. Additionally, prices may vary by specific regions within Oregon and Washington. For the most precise and up-to-date information on fuel prices and the causes for these price changes within your area, use the links below for AAA & GasBuddy.

If you have any questions, feel free to contact Star Oilco and speak to one of our fuel market advisors to discuss how the market can impact your business.