Why Business Owners Should Use Fuel Cards for Business Operations

Business owners typically consider these factors when deciding between a fuel card and a credit card for their fleet.

Control Over Spending

Fuel cards offer additional control as they restrict purchases to fuel and specific stations. Credit cards allow for multiple purchases, making expense tracking more challenging. This level of detail makes it possible for better budgeting and financial planning. Cardlock programs allow spending limits on individual cards. This provides an extra layer of control over fuel expenses, preventing employees from exceeding the designated budget.

Imagine having full control over card spending with automatic limits so you can continue to focus on your business operations without managing your fuel expenses.

Fuel cards:

- Limit purchases to fuel only.

- Restrict use to specific stations.

Credit cards:

- Allow for various purchases beyond fuel.

- Make expense tracking harder.

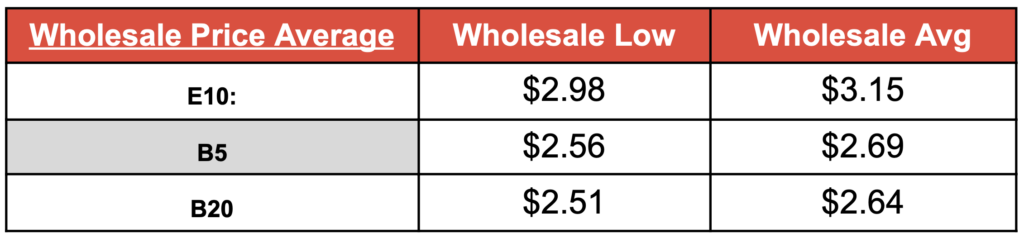

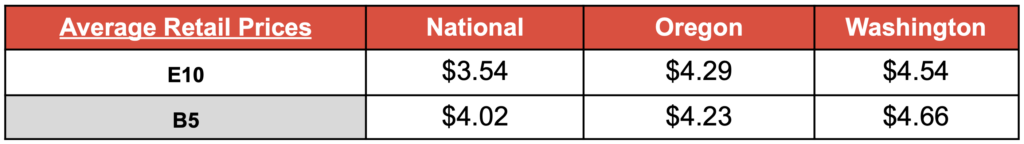

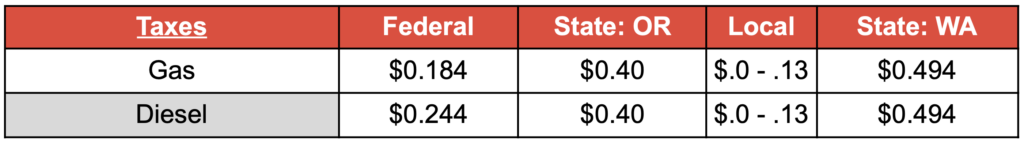

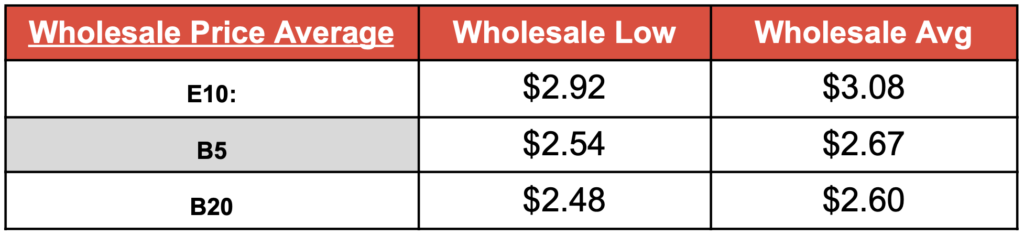

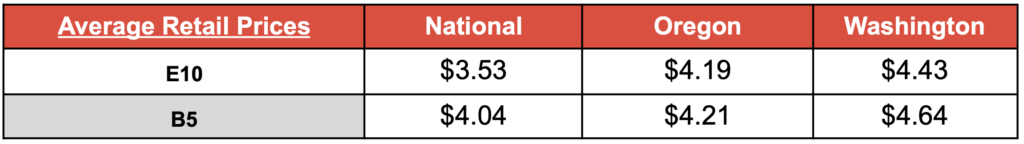

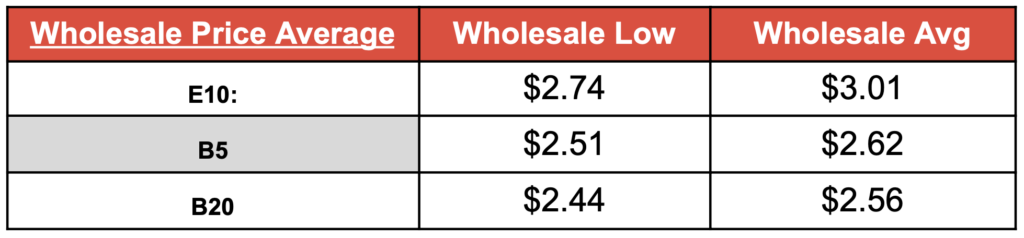

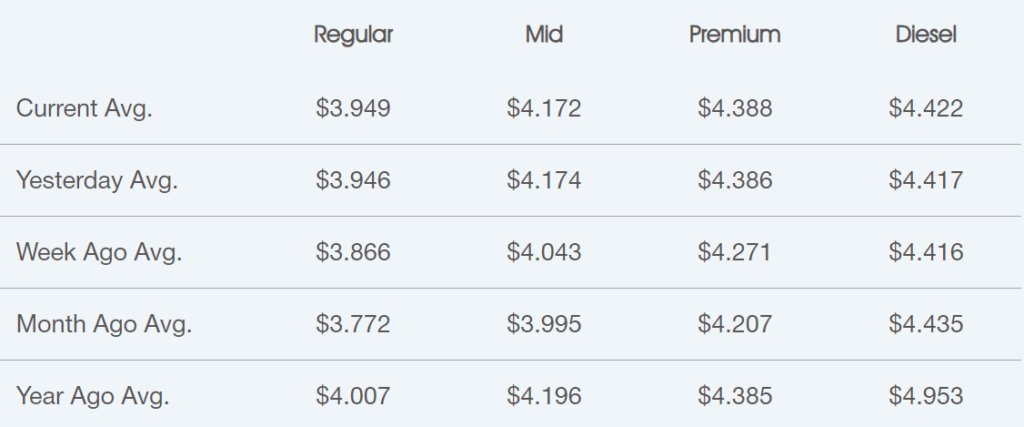

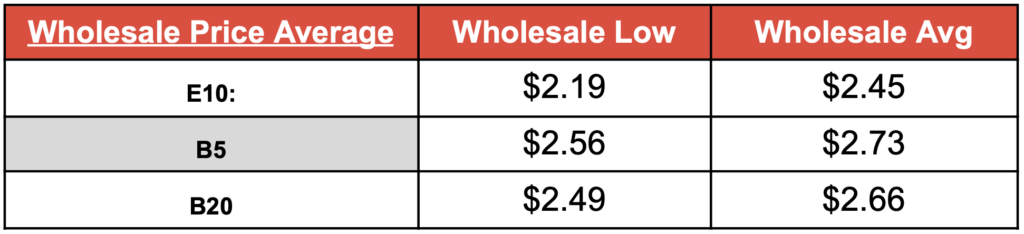

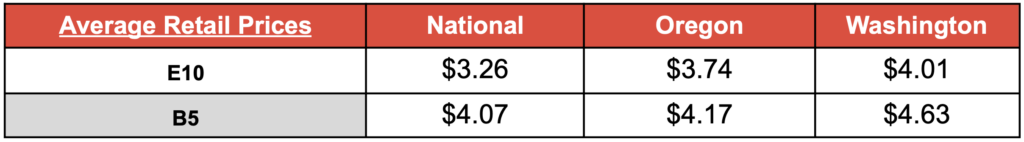

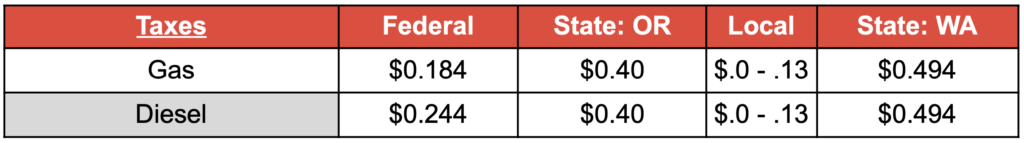

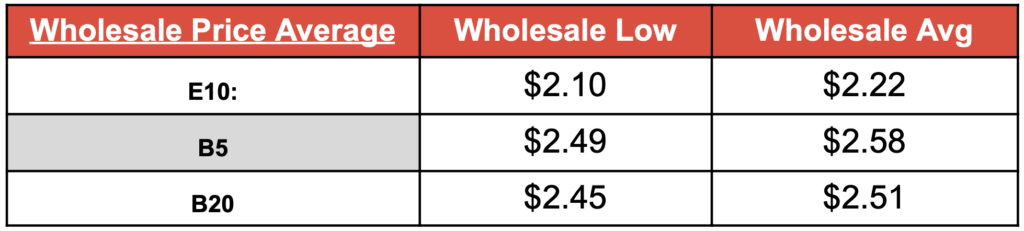

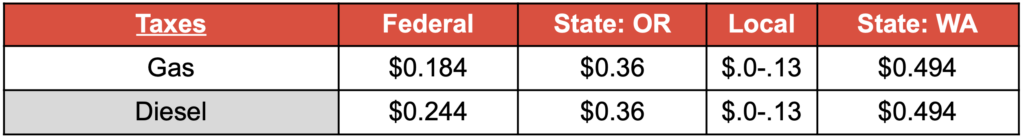

Fuel discounts

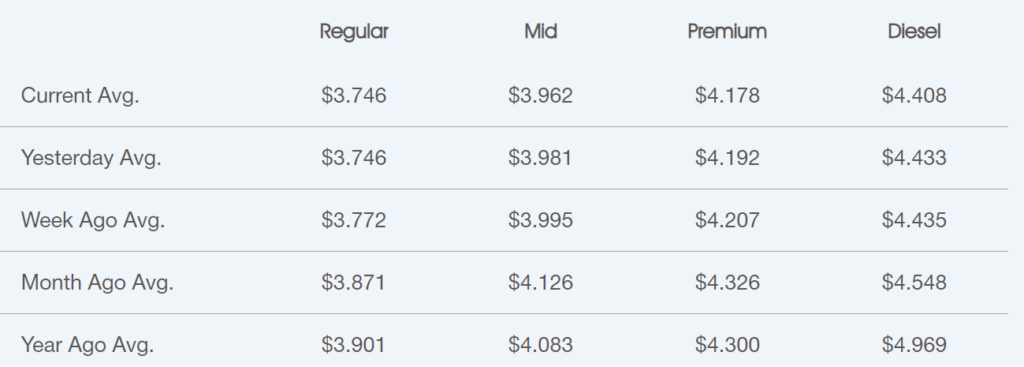

Fuel cards often come with discounts at participating stations, reducing fuel costs. Credit cards may offer reward points, but these could have less value than fuel discounts. With a fuel card, you get a discount right away, which can be several cents or even more per gallon. That can add up quickly depending on how much you drive. With a credit card, reward points may have a waiting period or expire after a certain amount of time. Additionally, fuel cards are typically easier to use than credit cards, as they are accepted at more gas stations.

Fuel cards:

- Offer immediate discounts at participating fuel stations.

- Discounts can be significant (several cents or more per gallon), leading to substantial savings with high fleet fuel consumption.

- Wide network of participating stations ensures easy access to discounts.

Credit cards:

- Reward points may offer less value than fuel card discounts. Earning points often translates to minimal gas discounts.

- Points typically come with restrictions like redemption minimums, blackout dates, and limitations on usable items.

- Using points often requires extra effort compared to automatic fuel card discounts.

Data and tracking

Fuel cards provide detailed data on fuel purchases, driver behavior, and fuel efficiency. Credit cards offer less data, making it more difficult to identify trends and optimize fleet operations. With a fuel card, companies can track individual driver behavior, such as what fuel stations they use, how much they purchase, and how often they make stops. They can also compare this data with other fleets to identify trends and areas for improvement. With a credit card, companies must rely on self-reported data, which can be unreliable and make it difficult to make informed decisions about fleet operations.

Fuel cards:

- Track fuel purchases (date, time, location, amount, gallons).

- Reveal driver behavior patterns (frequent stops, refueling times, locations).

- Enable monitoring of fuel efficiency (by tracking fuel use vs. mileage).

Credit cards:

- Limited data (total amount spent, merchant name).

- Hindering identification of fuel usage trends.

- Make it difficult to optimize fleet operations (due to lack of driver and efficiency data).

How could a fuel card help you better manage your fuel tracking and expenses automatically to save time and money for your business operations and your bottom line?

Security

Fuel cards typically have PIN verification and spending limits, minimizing fraud risk. Credit cards can be misused for unauthorized purchases. Additionally, fuel cards are more secure than credit cards because they are not linked to a bank account, limiting the amount of money that can be withdrawn. On top of that, fuel cards are easier to track and monitor than credit cards, making it easier to identify any suspicious activity.

Fuel cards typically have PIN verification and spending limits, minimizing fraud risk. Credit cards can be misused for unauthorized purchases. Additionally, fuel cards are more secure than credit cards because they are not linked to a bank account, limiting the amount of money that can be withdrawn. On top of that, fuel cards are easier to track and monitor than credit cards, making it easier to identify any suspicious activity.