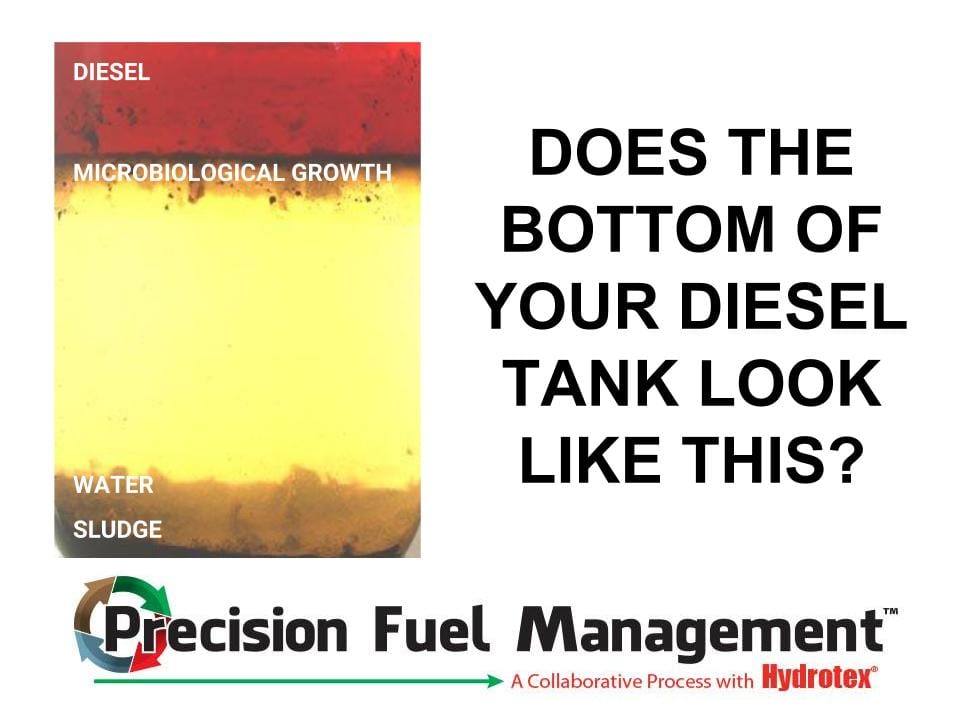

Do you know what your diesel fuel quality is?

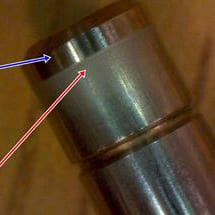

Find out what the bottom of your diesel tank looks like!

Call Star Oilco to get your diesel tested.

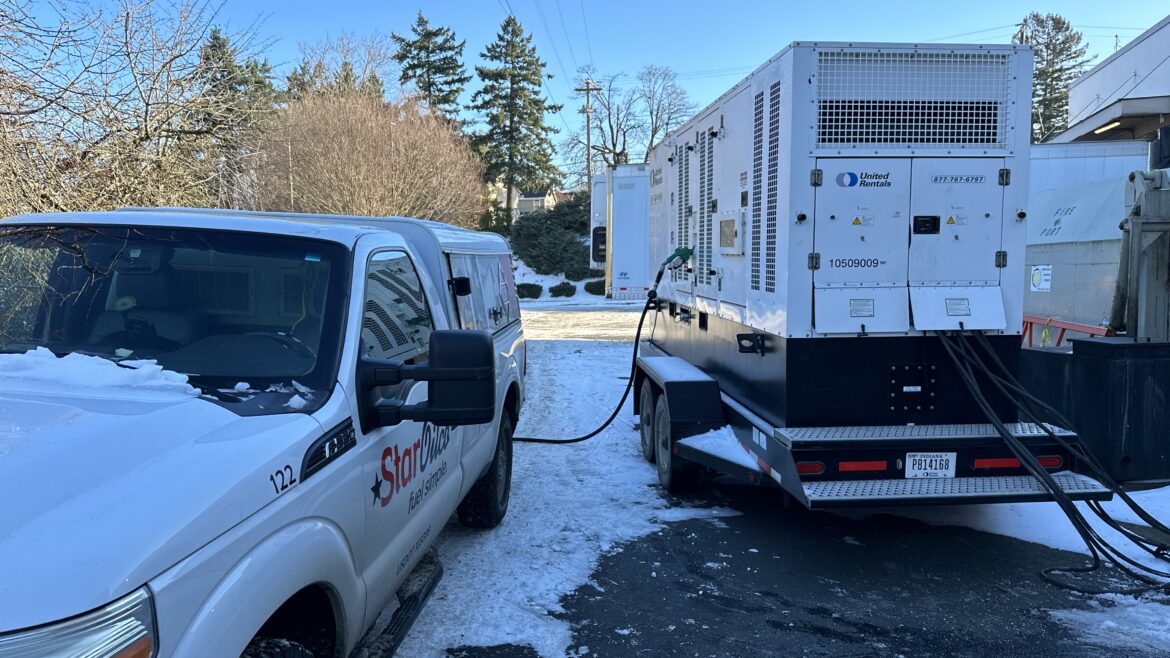

This winter, Star Oilco is offering complementary diesel fuel testing for any fleet operating in our service area. We are providing fuel quality testing in partnership with Hydrotex to assist fleets in our area struggling with containing the cost of fuel related maintenance. Typically a diesel lab test costs over $200 depending on the lab. Don’t let the hurdle of a scientific analysis stand between you and full knowledge of what is effecting your fleet.

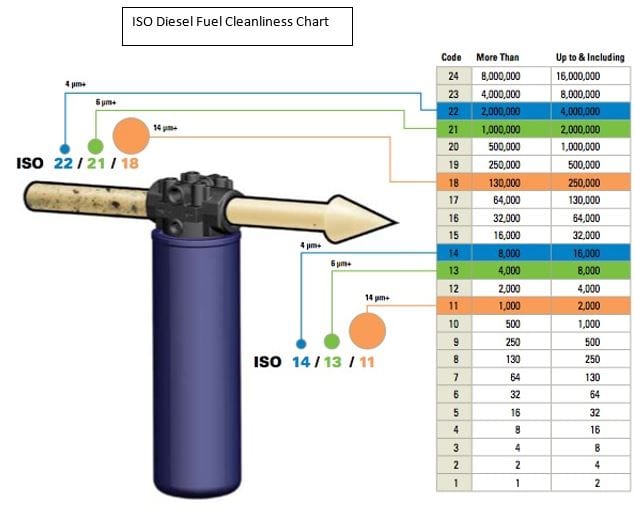

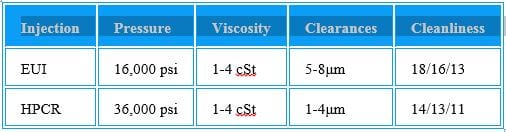

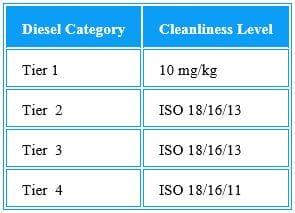

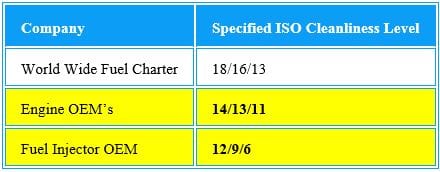

Since the move to Ultra Low Sulfur Diesel in 2007 along with moving changes in diesel refining and biodiesel mandates fuel quality has been a moving target. More importantly petroleum refiners and distributors follow an ASTM specification for diesel which is not as stringent as the ISO standards demanded by OEMs making the trucks on the road today. Water and dirt in fuel are robbing your fleet of money. Get a handle on it and move forward armed with that knowledge.

Star Oilco and Hydrotex can help you understand what is going on, what the quality of your tank bottom is, and what you need to do to reduce the cost of operating your fleet as it relates to diesel fuel.

Call Star Oilco and state you want to get your fuel tested for both ASTM and ISO specification. A member of our team will help you take the sample off of the bottom of your tank as well as from your dispensing nozzle.

Call Star Oilco today for have a sample taken and tested.

503-283-1256 or email OrderDesk@StarOilco.net