7 Ways to Stop Fuel Theft Before it Happens

IN YOUR BUSINESS TO REALLY SAVE ON YOUR COST OF DIESEL AND GASOLINE

Save money by managing your diesel and gasoline fleet cards. Know who, how, and where fuel is bought.

In the new world of diesel and gasoline over $5 you need a strategy to control where and how fuel is bought by your business.

Controlling your fuel expense can be time consuming and vital for any business. We recommend approaching it from a Human Resource management perspective.

Seize control of the use of fuel cards with real time feedback:

- Who is buying

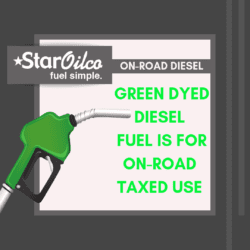

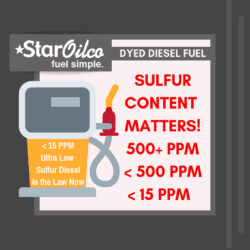

- What type of fuel

- Where it’s bought

- When are they buying

Set a clear standard and make sure you put controls on your fleet cards to ensure you keep honest employees from doing something that requires discipline. Below are some of the best practices for controlling your fleet’s fuel purchases.

Why Pacific Pride and CFN Fleet Cards?

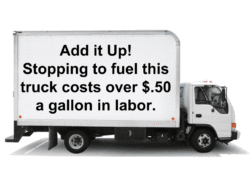

Often we are asked how to save money on fueling a small business fleet. Usually the biggest cost isn’t the pennies you save per gallon, but the gallons you can save by stopping theft. To save money on gasoline, make sure you aren’t paying for thieves to use your small business fuel cards.

Every fuel business seeks to avoid fuel slippage – the loss of fuel due to theft, waste or buying the wrong and/or more expensive fuel product. How can you secure the slippage, once and for all? These steps not only help with managing employees, but they can help you spot unusual purchases from stolen or skimmed cards. Skimming is when thieves hide a device that copies cards information and pin information. Thieves then clone the card and can attempt to use them in other locations. Using fuel cards vs Credit cards can save owners thousands of dollars. Employees have less access to non-authorized purchases and thieves can’t use fuel cards to purchase other items.

Star Oilco can help you establish a program to eliminate fuel slippage that includes an easy-to-use management process and enforcement of a “No Tolerance Fuel Theft Policy.”

Star Oilco has a simple and effective approach designed to empower you to easily manage your fuel cards.

Cardlock and secure fleet cards have been around since the 1970s and oddly enough, our competitors fail to field them properly. Star Oilco is here to help and would like to give you some simple and efficient practices to eliminate fuel slippage. We have an easy to implement strategy to lock down your cardlock and fleet cards in order to knock out the opportunity for fuel theft in your business.

By attaching the fuel cards to the vehicle and not the human being, you immediately break the driver’s belief that the company is providing fuel to them and not the company vehicle.

That’s why we recommend you attach the fleet card to the vehicle key chain and NOT in a driver’s wallet. For additional security, employ a Corporate Fleet Card that is secured by a PIN. Star Oilco recommends either Pacific Pride or CFN, both of which are in the Fuelman Network. Star Oilco will provide you with a keychain designed to hold up to two fleet cards.

Use a “Floating PIN” system where every member of the team has a secret PIN that is only to be used by them.

We recommend attaching fuel cards to the vehicle key chain and having each driver use their own secret PIN to purchase fuel. With this secret PIN, Star Oilco’s Fuel Cards track their name with every fuel purchase. Their name will appear next to the transaction on the bill and on an E-Receipt confirming who bought what, when, and where. This personalizes all fuel usage. Many companies already have a secret PIN policy around time cards and clocking in and out of work. This Best Practice stacks well with that.

Implement and enforce a “No Tolerance Fuel Theft Policy” that every employee must sign.

Policies vary but should generally include language that requires the use of a fleet card for fuel purchases, states that PIN use is tracked by employee, confirms that employees are held accountable for any wrongdoing associated with their PIN and acknowledges that fuel theft will lead to immediate termination. Star Oilco’s approach documents and provides evidence as well as real time knowledge for you to respond and ensure a fuel theft culture doesn’t grow in your business.

If you have fuel thieves in your business, make sure you document it at a Human Resource level. In many states a first time a fuel thief is caught they may still qualify for unemployment when dismissed. A No Tolerance Fuel Theft Policy when you on-board a new employee protects your from thieves getting away with it at the expense of your business.

Use E-Receipts to reinforce your fuel policy.

An E-Receipt is a real-time email showing who bought what fuel, when and where, as it happens. Make sure this E-Receipt is going to several levels in your office, where employees are paying attention to what your drivers are doing. If your fleet knows that their fuel purchases are completely transparent, they will think twice before doing something convenient for themselves over what the company needs. When a driver buys the wrong product, or was getting fuel out of route, you can follow up immediately to reinforce your fuel policies without waiting for a bill to show up at the end of the month. This is a great tool to spot additional transactions that may not be coming from your employees. “Get an email every time your fleet stops for fuel” is another article that talks about this if you would like more information.

Star Oilco can limit your fuel cards to work only during your business hours and/or within your territory.

Whether your territory is an entire state or limited to specific zip codes, you can define where your fleet can get fuel and where they cannot. And to avoid late night or early morning fuel theft, consider disabling your fuel cards during specified periods of the day or week, so that your cards don’t work when you don’t want them being used. This can easily be done as you need it by either contacting Star Oilco and asking us to do it for you, or by logging into your online Pacific Pride / CFN portal to set these restrictions yourself. Cards with limits are less attractive to thieves the more you can limit the usage the less appealing your card is for skimming thieves.

Set up your cards to only allow for a certain quantity or specific grade of fuel.

Consider limiting the volume of fuel purchased to match the size of a vehicle’s tank. Also, limit the number of transactions per day as well. That way, if for some reason that card gets stolen and someone has a working PIN, their theft is thoroughly limited.

Ask your vendor to review of all the cards and PINs you’ve used throughout the year.

Star Oilco seeks to do this annually. As per the state of Oregon (where Star Oilco is located), we receive a Fire Marshall audit every year and as they audit our cardlock records, we do the same and review every card and PIN for that year. You should do this too and Star Oilco can help. We recommend turning off all cards that are not being regularly used, which also allows you to adjust other details as needed. If you would like more information about this ‘What’s in a “Keep it Simple Fuel Audit”’ tells a little more about how we can review your current bill and simplify what you’re spending, where you’re spending it and give you tips on how to save some money.

Why use Commercial Cardlock over a retail gas station fleet card?

Commercial Cardlock locations in the CFN and Pacific Pride network are designed for business. Fast and easy in and out to save your business on labor as well as far more competitive prices especially on diesel. In Oregon where self serve gasoline is limited there are rules to using fleet cards at stand along cardlock locations. Here are the rules involved with getting a Pacific Pride or CFN commercial cardlock card which enables you 24-7-365 access to stand alone commercial fuel stations.

Oregon law has a 5% Biodiesel and 10% Ethanol fuel blend mandate.

Oregon law has a 5% Biodiesel and 10% Ethanol fuel blend mandate.