Every question Star Oilco has been asked about heating oil

Heating Oil FAQ (and not so FAQ)

It’s getting cold again in the Pacific Northwest, so it is time to take a look at some common questions we have been asked about Heating Oil. If you don’t see an answer to a question you have, please feel free to call, email, or message Star Oilco and we will gladly answer. We especially welcome questions that require research.

What is Heating Oil in Oregon?

Heating Oil in Oregon is diesel and can have a biodiesel blend as well. Diesel fuel has several grades either #1 or #2 Diesel. The number refers to the grade with #1 being called either “stove oil” or “Kerosene” as another term for it. Typically when someone is requesting or talking about heating oil they are talking about #2 Diesel dyed red to denote there are no on-road fuel taxes associated with the fuel.

How Does a Furnace Work?

There are several types of oil furnaces. The most common is a vaporizing burner. These furnaces typically work by taking a liquid combustible fuel, vaporizing it into a fine mist through a fuel oil nozzle, and igniting that mist into fire. That fire heats either air or water for your home’s comfort.

Heating Oil Fired Air Furnaces

Air furnaces usually move the air through a heat exchanger where a blower then moves air over the heat generated by your furnace, and finally the air is pushed through your home’s vents.

Heating Oil Fired Water Furnaces and Boilers

Boilers and Water furnaces heat a tank of water which is then distributed several different ways to heat your home. Either by moving hot water to radiators, radiant plumbing under your floor, or to a heat exchanger and blower which transfers the heat from the hot water into vents blown throughout your home.

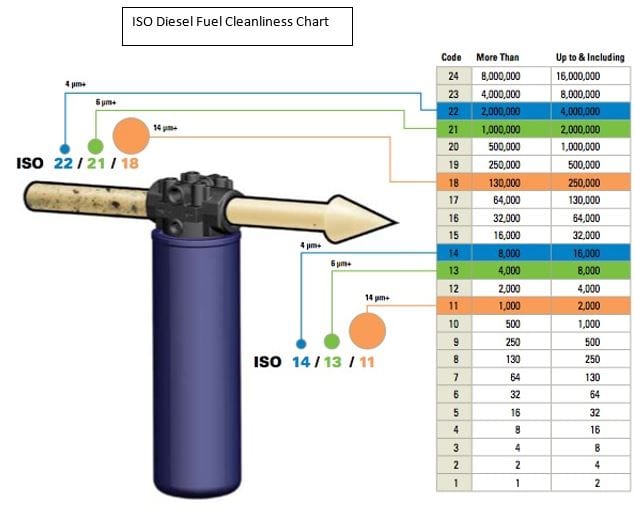

Heating Oil System prior to the combustion system

The parts leading up to the Burner of of an oil furnace system are simple. There is a tank to hold a reservoir of oil, a line from that tank (and sometimes a line back to it), a fuel filter, a fuel pump, and a vaporizing burner that combusts the heating oil into fire. Combustion of the fuel takes place in a fire box next to the heat exchanger. The heat exchanger takes on the heat of the flames to heat either air or water. In an oil furnace, the heat exchanger is assisted with a blower that pushes the hot air throughout your home to keep you comfy.

How Do I Check the Volume of Fuel in My Tank?

If you have an above or below ground heating oil tank you can confirm your fuel volume by the inches of fuel in the tank. If you have an above ground tank there is probably a tank gauge that can tell you an approximate volume in the tank. If you have an below ground tank you can confirm how many gallons are in the tank by putting a measuring stick or tape-measure into the tank.

You will want to confirm the size of the tank you have. Your oil provider will probably have an idea of what size your tank is by looking or historic deliveries. Star Oilco has a tank chart which will help. If you place a stick or tape measure into your tank and see how much fuel is in it you can compare that to a tank chart found on Star Oilco’s website. When delivering fuel you can “stick” measure the tank before and after the delivery. Compare these volumes with the delivery and you can often figure out your tank size based on the before and after volume lining up with how much fuel filled your tank.

To view Star Oilco’s Tank Chart please click HERE.

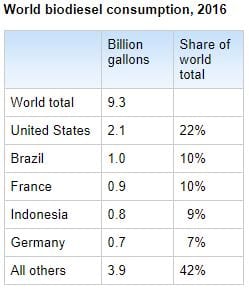

What is “Home Heating Oil” or “Residential Heating Oil?”

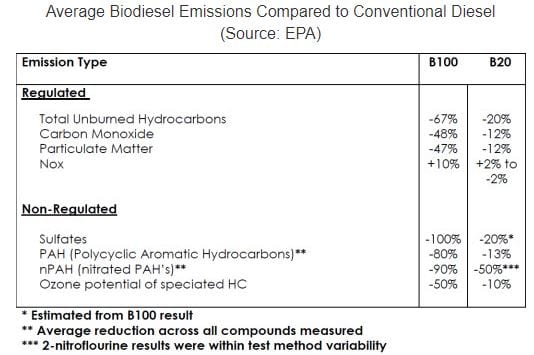

Home heating oil can be either a petroleum diesel fuel, bio-synthetic diesel fuel, or biodiesel fuel. In Oregon and Washington, home heating oil is typically ultra-low sulfur diesel fuel often containing between 5% and 20% biodiesel. Star Oilco’s standard home heating oil fuel is B5 dyed ultra-low sulfur diesel. Oregon mandates require that all diesel fuel sold contain a minimum 5% biodiesel. For that reason Star Oilco carries B5 or 5% biodiesel blends in our heating oil.

(NOTE: Kerosene sold by Star Oilco contains no biodiesel due to the reality that wick heaters cannot handle even a minute amount of biodiesel in them.) Star Oilco also carries a 20% biodiesel blend, called B20 Bioheat, for customers who want a cleaner burning low carbon fuel for their home.

What is Kerosene?

Kerosene is a heating oil product that is capable of being picked up and fed consistently by a wick heater. Kerosene is a diesel product that is very similar to the fuel used for over the road trucks. The big difference is that kerosene is a “lighter end” distillate fuel, which means it has a lighter specific gravity. This lighter characteristic means that it also works better in certain systems like wick heaters, pressure washers, and pot burner stoves.

Can Heating Oil be Used in a Kerosene Heater?

It depends on what type of system the kerosene heater is operating with. If you have a wick heater it will not work with heating oil. You will likely have to replace the wick to get it to work again as diesel will not readily drawn into the wick. Even if it does, it will burn far dirtier. If it is a pot burning system like a Toyostove or Monitor heater, then it will burn ultra low sulfur heating oil. Increased maintenance is to be expected on the pot burner, as there is a likelihood of more coking (crusty black soot build up) to occur inside that system.

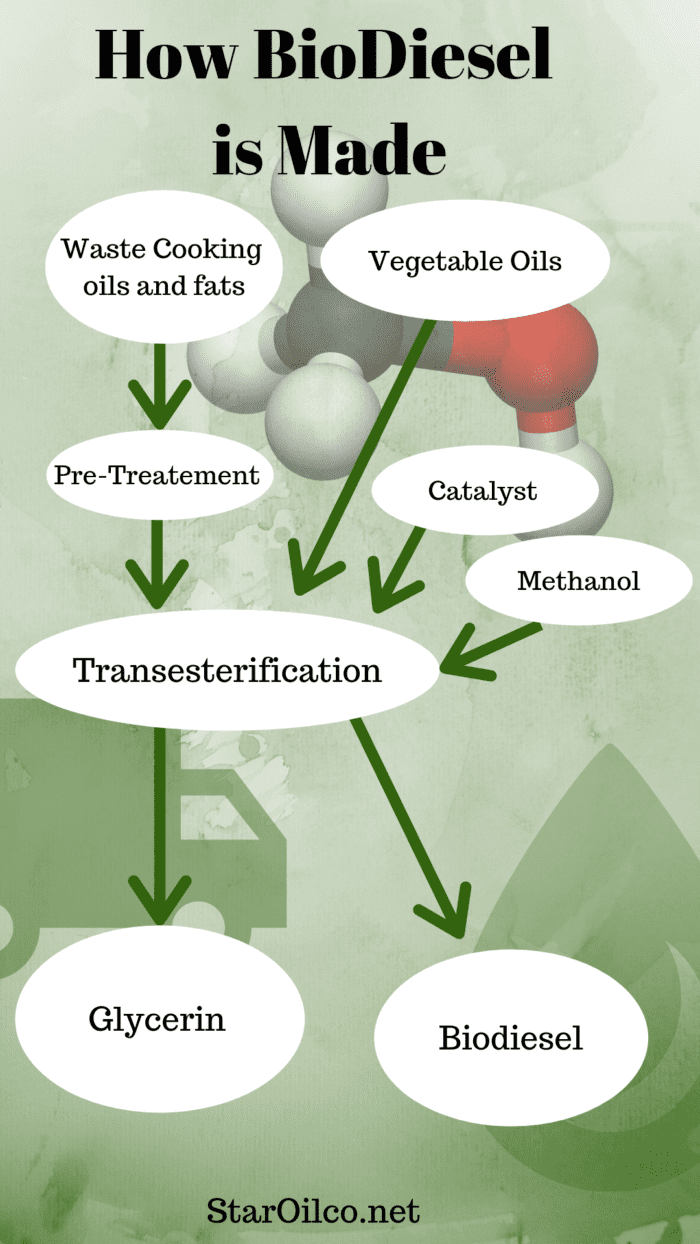

What is “Bio Heating Oil” or Bioheat?

Bio heating oil and bioheat refer to heating oil products with a blend of biodiesel in them. Typically bioheat is a blend between 5% to 20% biodiesel with ultra low sulfur diesel for a clean burning and low CO2 heating fuel.

For a really in-depth look at biodiesel used as a heating oil check out this article.

Will Heating Oil Run a Diesel Engine?

Yes, heating oil will run in a diesel engine. Heating oil is diesel. Be aware though that on-road vehicles must only run clear diesel fuels. If caught using heating oil in an on-road vehicle in Oregon and Washington, the fines can run in the tens of thousands of dollars. Heating oil can also be dyed to signify it isn’t for on-road use.

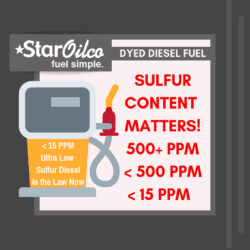

Also be aware that even many off-road pieces of equipment and generators need ultra low sulfur diesel to operate without very expensive maintenance. Heating oil can have low sulfur or even high sulfur contents that could cause real issues for modern clean diesel engines. Some consideration is needed prior to burning a fuel marked “heating oil” in a diesel engine.

What Fuel Do I Need?

Consult your furnace, stove, boiler or water heater’s factory recommended specification. Typically it’s Number 2 Diesel unless it is a stove pot or wick heated system. If you have a furnace or a boiler in your basement, you can assume it’s heating oil. Call a licensed and bonded heating oil furnace technician to tune up your furnace to confirm for sure. If you do not have one, Star Oilco can refer you to a number of reputable long-time firms who can help.

What Are Additives and Are They Worth it?

Heating oil additives are added to fuel in order to improve it’s long term storage and performance. They are worth it and most reputable heating oil providers additize their fuel without an extra charge. This is because most heating oil customers store their fuel for long periods of time. If you are planning on storing heating oil for years you will need a fuel additive to keep that fuel in the quality needed for your furnace.

Star Oilco provides a premium diesel additive called Hydrotex PowerKleen to every gallon of heating oil we sell. Beyond this stabilizers, if you are planning on storing fuel for years we recommend ValvTect Plus 6. You will want to treat your fuel with a biocide like ValvTect Plus 6 to will kill any bacteria, yeast, algae, or other biological organism that can grow inside your heating oil tank.

What Does Heating Oil Smell Like?

Heating oil smells like diesel. It is a diesel product and often, depending on location, it is the same as on-road diesel. It may be dyed to denote that it is an off-road fuel with a untaxed use. Heating oil is dyed red in the Pacific NW to show it is off-road diesel.

What is Heating Oil #2?

Heating Oil #2 is number 2 diesel or the standard diesel sold in most places for on-road diesel use. Heating Oil #2 is a slightly different specification than on-road diesel that allows for more sulfur. That is a big difference as far as the EPA is concerned. On-road and off-road vehicles in the U.S. are required to use ultra-low sulfur diesel. Heating oil systems can use low or high sulfur diesel fuels. Ultra low-sulfur diesel is the most common Heating Oil #2 fuel that is delivered by Star Oilco since it is a superior and cleaner burning fuel, in our opinion.

Where can I buy heating oil at the pump?

In the Pacific NW heating oil is ultra low sulfur diesel. Therefore, you can buy any diesel sold at a retail gas station, truckstop, farm supply or other liquid fuel seller. Heating oil is dyed red to show that it is not taxed for on-road fuel use. Other than that red dye, typical auto-diesel will work in your oil furnace if you need to supply it from a diesel can.

At What Temperature Does Heating Oil Freeze?

Heating Oil Gel Point:

In the Pacific NW we expect number 2 diesel heating oils to be operable beyond -10 degrees. The record cold weather in the Willamette Valley is above 0 degrees (recent decades 16 degrees was our record low in Portland). We do test and add additives to our fuels to ensure they meet this specification even if they contain 5% biodiesel blended into heating oil.

Kerosene Gel Point:

Kerosene fuels (Number 1 Diesel, Number 1 Stove Oil, and Kerosene labeled fuels) are expected to be good below -30 degrees and are designed to be used in high altitude applications. (Kerosene and jet fuels are often the same specification in the Pacific NW.)

B20+ Biodiesel Gel Point:

Biodiesel blends of B20 and above are assumed to be good to 20 degrees but if Star Oilco expects below-freezing weather, we highly recommend B5 as your delivered fuel. B99 biodiesel typically gels at 40 degrees, so it’s not a winter fuel unless you have a system designed to keep the fuel warm in the middle of winter.

What do “Oil Heating,” “Oil Fired Heater,” or “Oil Furnace” Mean When Referring to a House?

“Oil Heat” or “Oil Fired” refers to a heating system reliant on burning heating oil. Typically this is by use of a vaporizing burner that takes the combustible liquid that is heating oil and vaporizes it through a nozzle into an igniter that causes it to burn. This system burns the heating oil, creating a great deal of heat that can warm air, water, or both to heat a home or commercial space.

Can Heating Oil Fumes Make You Sick? Are the Fumes Harmful, Dangerous, or Toxic?

NOTE: IF HEATING OIL HAS BEEN INGESTED PLEASE SEE A MEDICAL PROFESSIONAL!

Heating oil by itself is not dangerous or toxic if it come in contact with your skin. It is easily washed off with soap and water. A small amount of diesel spilled on the surface of the ground, typically will break down on it’s own in the presence of the environment. A small amount spilled on concrete or asphalt can be cleaned up easily with dish soap and water. If your tank leaks and heating oil is soaked below ground this will not break down easily and will take professional help to treat.

The exhaust from heating oil systems contains carbon monoxide and carbon dioxide as well as particulates. Heating oil and other diesel exhausts are very dangerous and toxic and should be avoided. Do not allow exhausts of any kind to collect in an enclosed space.

Can Heating Oil Evaporate?

Heating Oil’s vapor point (the temperature it turns to vapor and evaporates) is around 140 degrees Fahrenheit. Heating oil ignites at 160 degrees. Typically in the Pacific NW the temperature (especially outside) is well below the vapor and flash point of diesel fuels including heating oil and kerosene. If spilled it will not usually evaporate. You can clean heating oil and diesel up with regular dish soap and water.

Can Heating Oil Vapor Explode? Can They Ignite?

Heating oil ignites at 160 degrees. So unless the temperature is that high an explosion is not a risk. Fire Code regulating heating oil tanks and placement takes this concern into account. So typically except in extreme scenarios heating oil vapor does not pose an explosion risk.

If you drop a match into a cup of heating oil at room temperature it will go out. If you hold a match to the surface of the heating oil in that cup the flame will get large and bright but the heating oil itself will not ignite. Heating oil needs to be vaporized before it will ignite. It is a combustible fuel so it must be in a vapor form to light. The vaporizing nozzle of your heating oil furnace turns diesel into a vapor mist easily ignitable.

Can Heating Oil Go Bad? How Long Can I Store Heating Oil?

Yes, heating oil can go bad. If you are planning to store heating oil for longer than a year, you should use a diesel additive that stabilizes fuel for long term storage. If you are storing the fuel as a back-up where you might go years without using it, you should also consider adding a biocide to ensure nothing grows in your tank. The two biggest threats to your fuel staying in specification are water and biological growth. Biological growth occurs inside the water that can collect in your tank bottom naturally through condensation over time.

Star Oilco treats 100% of our dyed fuels with Hydrotex Powerkleen to ensure that it is stable for storage for over a year. If you need to store it longer than that, we further recommend adding a desiccant breather to scrub moisture out of the air when your tank breaths, which protects it from additional water.

For more on additizing your heating oil for long term storage please follow THIS link.

Can a Heating Oil Tank be Outside?

Yes, heating oil tanks properly installed outside are perfectly safe and capable of ensuring your fuel stays clean and dry.

Are Oil Tanks Regulated?

Yes, at several different levels. With residential use, there are local jurisdictions’ building permit requirements for installation and safety. With commercial use, there is the same building permit regulation and usually an added level of Fire Marshall sign-off for siting of any tanks. In rural areas, regulations are different if the tank is associated with an agricultural use.

In Oregon and Washington, a 90 day temporary tank for construction purposes (to move from one tank to another in a formal process) is usually allowed, but you should ensure the temporary tank is a double wall tank and is in a safe place. If your tank leaks (or even if there is a suspicion of a leak), the Oregon Department of Environmental Quality and Washington Department of Ecology have an involved process to close out a leaking oil tank.

Do I Need to do Maintenance on My Furnace? How Often?

Yes, you need to ensure you maintain your oil furnace. Star Oilco recommends getting a tune up annually or at least every other year. If you are seeking a referral to a HVAC company that specializes in oil heat, call Star Oilco’s office 503-283-1256 and ask for a list of qualified license and bonded companies we recommend. You also want to check your oil furnace for water annually. Star Oilco can stick your tank for water at no charge upon request with a fuel delivery.

One of the great benefits of oil heat is that oil furnaces are known to last for over fifty years if maintained properly. Natural gas and propane furnaces typically wear out every ten to twenty years dependent on their construction. The primary wear consideration on any furnace is the heat exchanger. The heavy steel part takes the flame of burning fuel, transmits this heat to the air, and is then pushed to heat your home. Oil furnaces must be tuned up every year or two to ensure the heat exchanger is cleaned.

If you do not service the heat exchanger, it will collect soot. Soot insulates the heat exchanger unevenly and causes wear that will eventually lead to a crack. If a heat exchanger is cracked, the furnace is no longer safe to operate. Additionally, an annual tune-up will pay for itself by ensuring your furnace is burning at peak efficiency. You will want to replace your furnace air filter regularly on an annual basis.

How Do I Reduce My Consumption of Heating Oil?

Tuning your furnace annually or every other year is highly recommended. Adjusting the fuel air mixture for the most efficient combustion goes a long way to ensure you use as little heating oil as possible. Star Oilco has witnessed fifty and even seventy year oil furnaces operate at modern efficiencies when maintained regularly over their lives. Today, there are a host of high efficiency oil furnaces manufactured and supported to reduce your cost of fuel. Additionally, confirming the envelope of your home is not drafty or needlessly wasting heat can go a long way in reducing your heating expenses.

How Can I Reduce the Cost of My Heating Oil?

The price of heating oil fluctuates frequently due to market conditions. Comparison shopping is your best way to ensure you pay the best possible price. One web based tool we have heard customers like to use to save time while shopping for heating oil is Fuelwonk.com. It is free and easy to use.

Best Practices with a Fuel Tank

Even though the cost of fuel is dependent on the market and out of our control, there are best practices to reduce the amount of oil you’ll need. The temperature you keep your house will affect how much oil you go through. Keeping your temperature higher will lead to more oil burned during the winter months. How insulated your home is will also affect the amount of oil you burn. Having poor insulation will result in having your furnace running hotter for longer periods of time, increasing fuel use. Annual maintenance of your furnace will keep your furnace operating at top efficiencies. Having a well working and operating furnace will keep costs down by not wasting oil on an underperforming unit.

Discounts

Star Oilco also has a number of discounts and programs for price reduction. We offer $.05/gallon veteran and senior citizen discount. We frequently have discounts on Google and our social media pages so make sure to check those out. Mention where you saw it to receive the discount.

Heating oil customers at Star Oilco have the opportunity to enroll in our Equal Pay program. The program allows you to make equal monthly payments on future heating oil deliveries. As an Equal Pay customer, you will receive a discount of .20 cents per gallon on all heating oil deliveries. We also have an Autofill program which dictates you receive our best price as well as automatic deliveries. You don’t have to keep track of your fuel or when you need a delivery. We do the work for you!

If you do not like our price and someone else is cheaper let us know. We will match their price.

Will Heating Oil be Phased Out?

Heating Oil is a modern fuel that uses today’s heating oils and biofuels. The investments in research and development for heating oil furnace by the National Oil Research Alliance to use a wider variety of biofuels in higher lower CO2 blends have kept heating oil relevant in many applications. As a heating fuel, it’s use will become more rural than urban rather than a phase out. As it is today, the use of heating oil will be used where natural gas is not available especially if the temperatures get below zero. Urban adoption of natural gas has increased, as it’s cheaper than heating oil due to increased fracking development of petroleum.

What are “Degree Days?”

Star Oilco uses a Degree Day system for our customers on Automatic Keep-Full Service. We fill your tank before it needs it automatically. A statistical regression analysis correlates your typical use of heating oil in your home and the weather. Our systems will track your usual fuel usage and we automatically schedule delivery to keep your tank full.

What is The Energy Content or “BTU’s”?

The technical term “BTUs” refers to “British Thermal Units” which is a measure of energy content of a fuel. The energy content of diesel fuels can vary slightly by regions and specifications of those regions. In the Pacific Northwest, heating oil is typically Ultra Low Sulfur Diesel with a blend of biodiesel content. This can range from 5% to 20% biodiesel added to the fuel. This means the exact BTU measured for a gallon of heating oil an slightly vary.

Source: US Alternative Fuel Data Center Fuel Properties Comparisons

Ultra Low Sulfur Diesel: 128,488 BTUs to 138,490 BTUs per gallon.

B5 Biodiesel is presumed to be about the same BTUs as ULS Diesel.

B100 Biodiesel: 119,550 BTUs to 127,960 BTUs per gallon.

B20 Biodiesel: 126,700 BTUs to 136,384 BTUs per gallon.

When you use biodiesel, you’re using CO2 that is being captured by the growing plants or the waste. This is current CO2 you aren’t adding to the net sum in the environment.

When you use biodiesel, you’re using CO2 that is being captured by the growing plants or the waste. This is current CO2 you aren’t adding to the net sum in the environment.