BioDiesel Feedstocks – Hemp Oil & High IV and Low IV Hepar

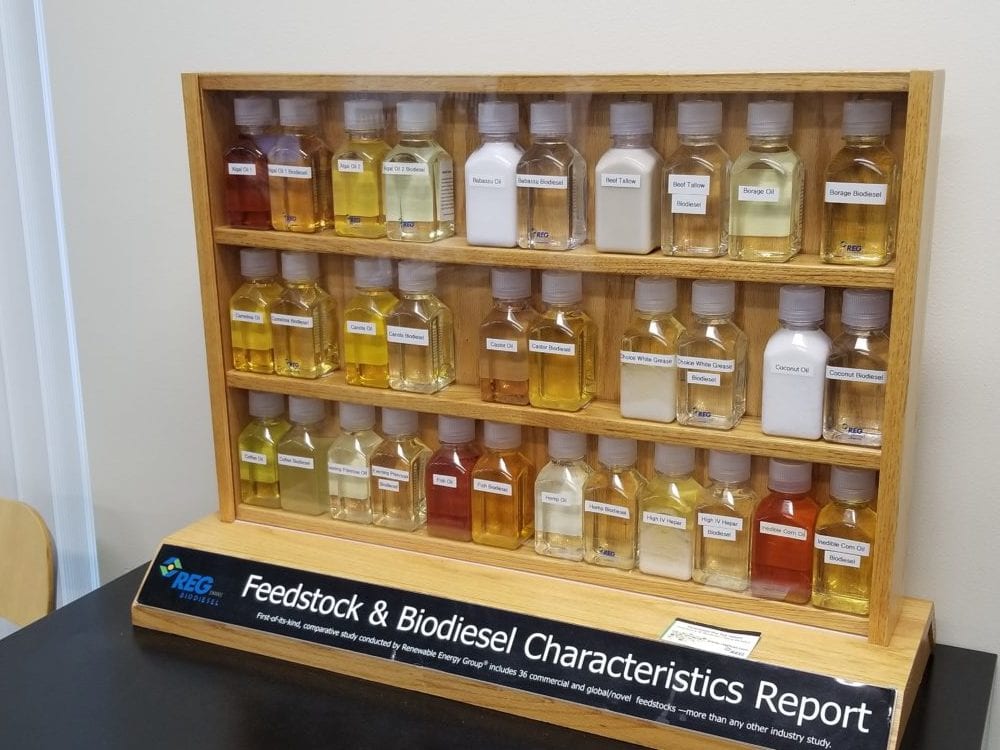

In this post we are going to continue our deeper look into different types of feedstock that Renewable Energy Group (REG) studied in 2009 in the Feedstock and Biodiesel Characteristics Report. The feedstocks we are looking into are Hemp Oil & High IV and Low IV Hepar. Here is a link to the main page of feedstocks we have examined so far.

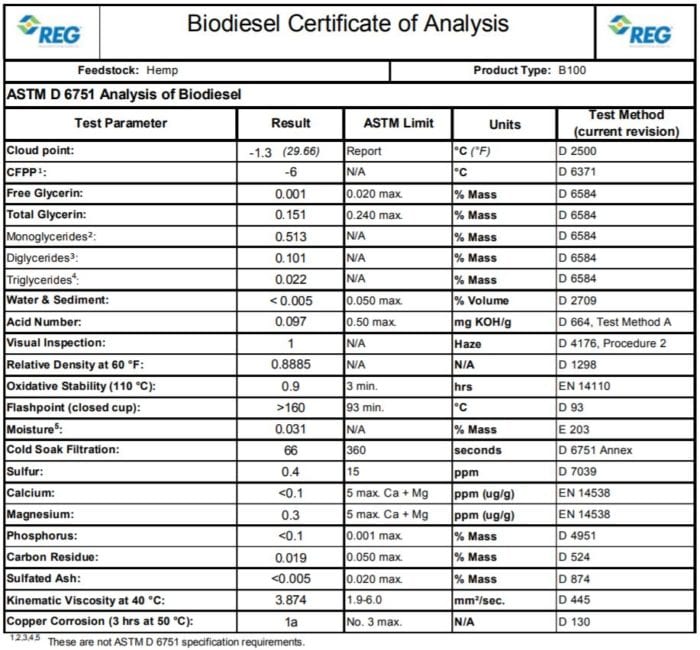

As a reminder B20 Biodiesel (B20 stands for 20% biodiesel and 80% petroleum diesel) is the drop in solution for reduced emissions in today’s modern diesel engines. To understand some of the alternate feedstocks that can be used for biodiesel, we are examining a report that Renewable Energy Group (REG) produced in 2009. All certificates of analysis and results are for B100.

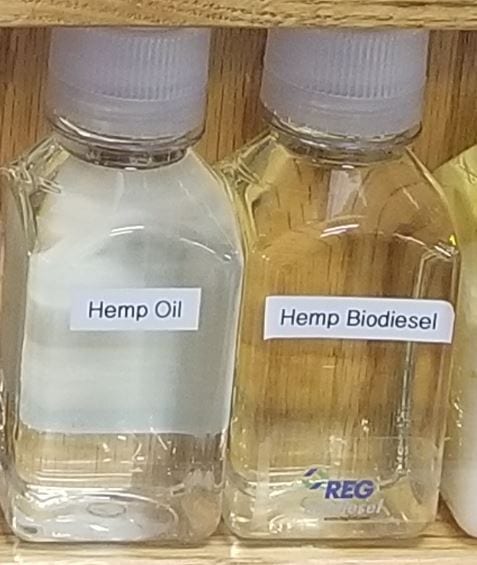

Hemp Oil

Hemp seed oil comes from the plant Cannabis sativa and contains significant amounts of linolenic acid. The hemp oil in this study was sourced out of Canada and these seeds have an oil content of 33 percent.

Based on Industrial Hemp Regulations in Canada:

“Industrial hemp includes Cannabis plants and plant parts, of any variety, that contains 0.3% tetrahydrocannabinol (THC) or less in the leaves and flowering heads.

Industrial hemp also includes the derivatives of industrial hemp plants and plant parts. These do not include the flowering parts or the leaves.

Examples of derivatives that are considered industrial hemp include: hemp seed oil (oil derived from seed or grain) and hemp flour.”

THC is the chemical that has psychoactive properties and is what makes the cannabis Marijuana vs Hemp.

This biodiesel sample was created with seed oil that contained less than .03% THC.

Cannabis sativa is an annual flowering plant that originates in Central Asia and is now spread world-wide. The uses of the plant include seed oil, food, recreation, medicine and industrial fiber. (Source)

The centuries of early human cultivation of these plants has created a large variety of strains that look, grow and act different. Pictured is an example of what a Hemp or Marijuana plant looks like in bloom.

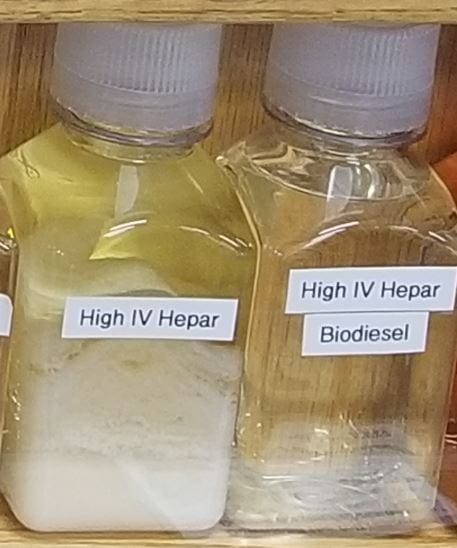

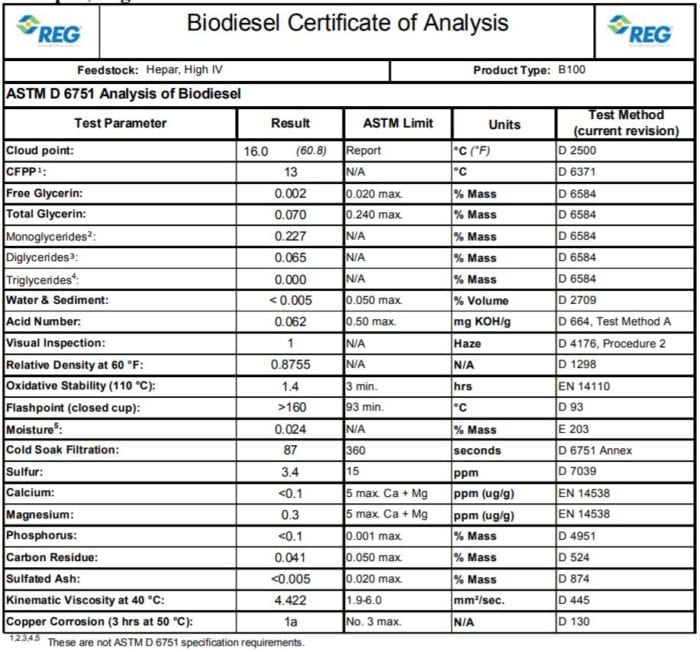

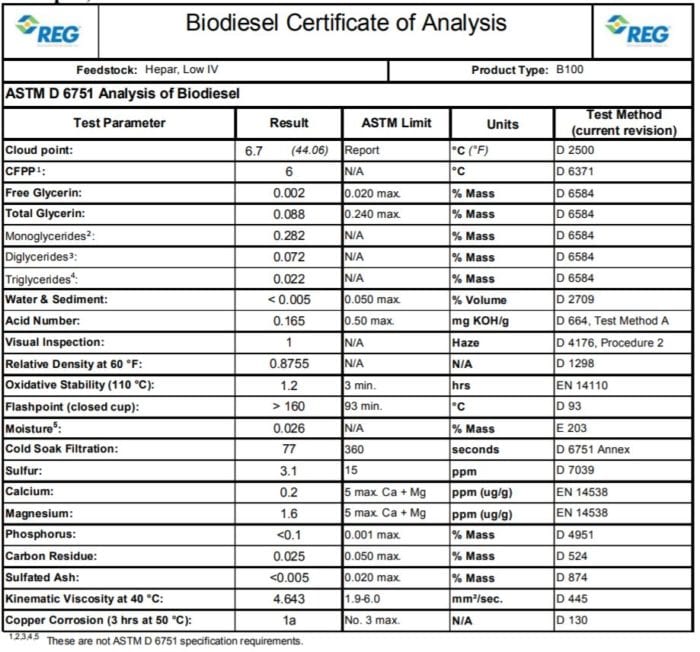

Hepar, High Iodine Value and Low Iodine Value (IV)

In this situation, Hepar is a byproduct of the heparin manufacturing process. Pharmaceutical grade heparin is derived from the mucosal tissues and of animals, such as pig intestines or cow lungs. (Mucosal tissues are part of the immune system it is the barrier between potential pathogens and the body.) Heparin is a medicine that is used as an anticoagulant. Since the creation of Heparin is a industry secret, it is difficult to find much information about the byproduct Hepar.

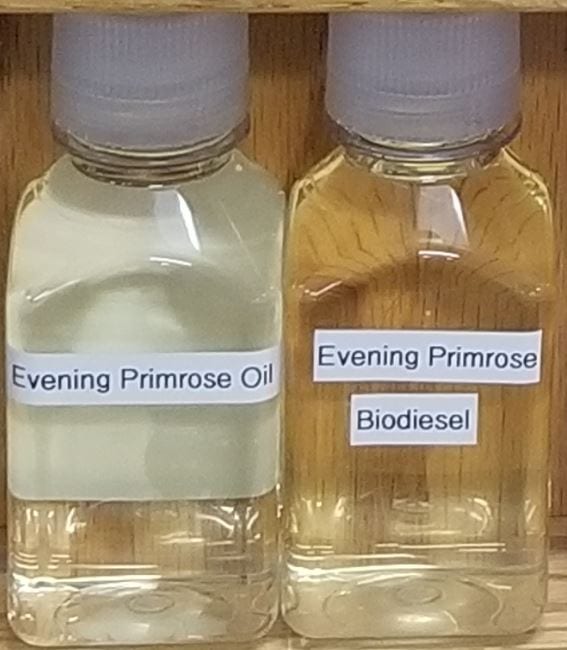

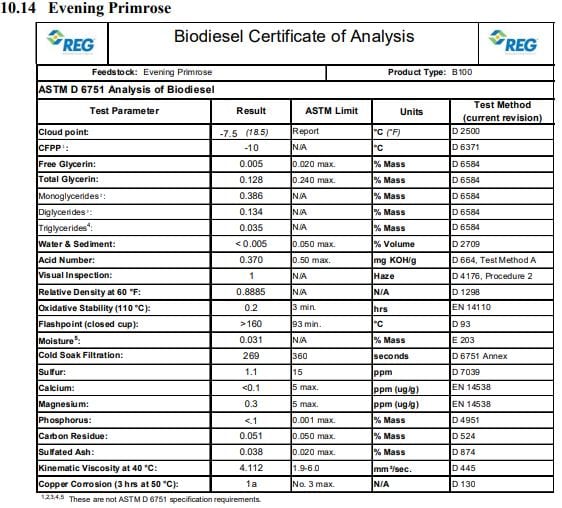

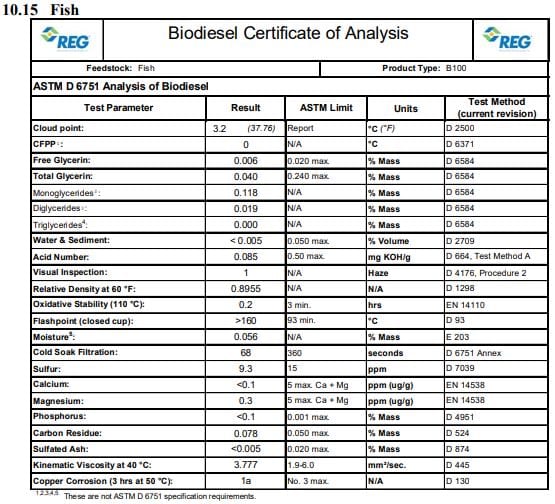

Last article for biodiesel feedstocks was Evening Primrose Oil & Fish Oil

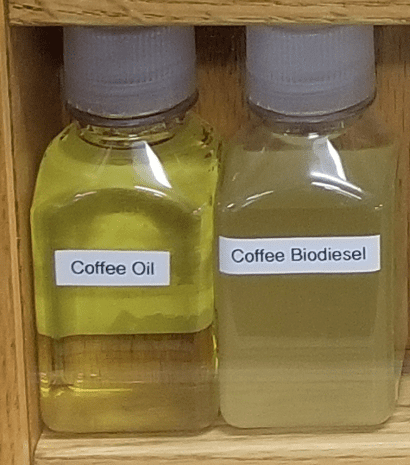

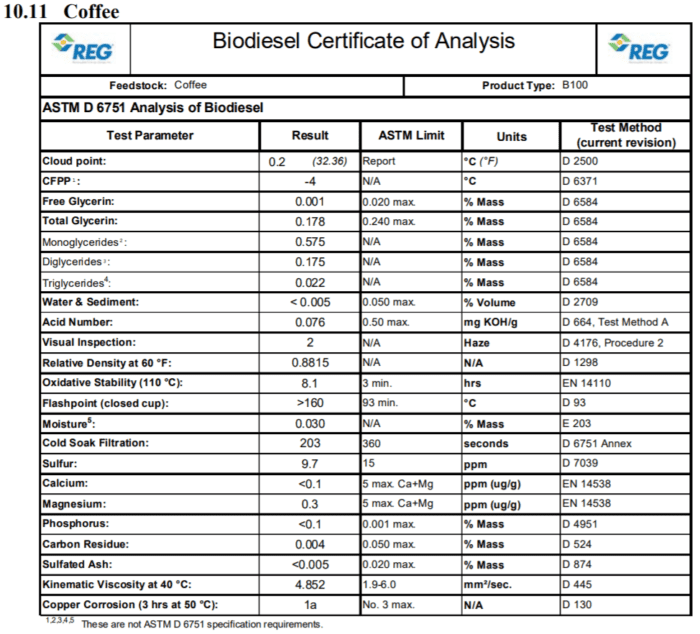

Coffee comes from roasted coffee beans, these “beans” are actually the seeds from berries of the Coffea species, with the two most common species being C. arabica and C. canephora. People have been drinking coffee since the 15th century. Coffee plants are evergreen shrubs that can grow up to 15 feet tall. They have glossy, dark-green leaves about 4 to 6 inches long. Brazil, Vietnam, and Colombia are were most of the coffee is coming from.

Coffee comes from roasted coffee beans, these “beans” are actually the seeds from berries of the Coffea species, with the two most common species being C. arabica and C. canephora. People have been drinking coffee since the 15th century. Coffee plants are evergreen shrubs that can grow up to 15 feet tall. They have glossy, dark-green leaves about 4 to 6 inches long. Brazil, Vietnam, and Colombia are were most of the coffee is coming from.

Ricinus communis is a fast-growing shrub type plant that can reach the size of a small tree. This perennial flowering plant is native to the southeastern Mediterranean Basin, Eastern Africa, and India, but grows easily throughout tropical regions. It is not a cold hardy plant, although in a suitable environment it can become invasive. Castor bean plants are grown as ornamental plants throughout the world and are used extensively as a decorative plant in parks and public areas. The castor bean plan will grow rapidly in a single season, about 6-10’ tall. Ornamentally, it is most valued for its huge, palmately (having four or more lobes or leaflets radiating from a single point) 5-11 pointed lobes, toothed, glossy green leaves (each to 1-3’ across) and round, spikey, reddish-brown seed capsules. Small cup-shaped, greenish-yellow apetalous (lacking flower petals) spikes which are not particularly showy. Different cultivations of the plant result in dwarf and large plants, some with attractive reddish, bronze or purple leaves and bright and colorful flowers.

Ricinus communis is a fast-growing shrub type plant that can reach the size of a small tree. This perennial flowering plant is native to the southeastern Mediterranean Basin, Eastern Africa, and India, but grows easily throughout tropical regions. It is not a cold hardy plant, although in a suitable environment it can become invasive. Castor bean plants are grown as ornamental plants throughout the world and are used extensively as a decorative plant in parks and public areas. The castor bean plan will grow rapidly in a single season, about 6-10’ tall. Ornamentally, it is most valued for its huge, palmately (having four or more lobes or leaflets radiating from a single point) 5-11 pointed lobes, toothed, glossy green leaves (each to 1-3’ across) and round, spikey, reddish-brown seed capsules. Small cup-shaped, greenish-yellow apetalous (lacking flower petals) spikes which are not particularly showy. Different cultivations of the plant result in dwarf and large plants, some with attractive reddish, bronze or purple leaves and bright and colorful flowers.

Brassica Napus is also known as rape or rapeseed. The name rape is derived from the Latin word for turnip, rapum. Brassicaceae is the family of which mustard, cauliflower and cabbage belong. The name Canola comes from the contraction of Canada and ola, meaning oil. Developed in 1970s by researchers from the University of Manitoba and Agri-Food Canada, the use of the term Canola means that the oilseed meets certain standards.

Brassica Napus is also known as rape or rapeseed. The name rape is derived from the Latin word for turnip, rapum. Brassicaceae is the family of which mustard, cauliflower and cabbage belong. The name Canola comes from the contraction of Canada and ola, meaning oil. Developed in 1970s by researchers from the University of Manitoba and Agri-Food Canada, the use of the term Canola means that the oilseed meets certain standards.

The starflower is easily grown in average, dry to medium moisture, well-drained soils in full sun to light shade. In addition this plant tolerates poor soils and drought. It is native to Mediterranean region and is an annual that will continue to propagate itself in a garden by reseeding. The plant grows to 2 to 3 feet tall and the flowers are commonly blue, although pink and white flowers are commonly cultivated. The flowering season is relatively long from June to September and in milder climates the starflower will bloom for most of the year.

The starflower is easily grown in average, dry to medium moisture, well-drained soils in full sun to light shade. In addition this plant tolerates poor soils and drought. It is native to Mediterranean region and is an annual that will continue to propagate itself in a garden by reseeding. The plant grows to 2 to 3 feet tall and the flowers are commonly blue, although pink and white flowers are commonly cultivated. The flowering season is relatively long from June to September and in milder climates the starflower will bloom for most of the year.

This flowering plant is native to Europe and Central Asian areas. Camelina plants grow from 1 to 3 feet tall, are heavily branched and produce seed pods with many small, oily seeds. Some varieties of camelina contain 38-40 % oil. Camelina can be grown in arid conditions and does not require significant amounts of fertilizer.

This flowering plant is native to Europe and Central Asian areas. Camelina plants grow from 1 to 3 feet tall, are heavily branched and produce seed pods with many small, oily seeds. Some varieties of camelina contain 38-40 % oil. Camelina can be grown in arid conditions and does not require significant amounts of fertilizer.