How to Prevent Diesel Fuel from Gelling in Low Temperatures

When the chill of winter arrives in Portland and across Oregon, diesel engines face a unique challenge. Cold temperatures can transform diesel fuel from a fluid state into a gel-like substance, leading to significant engine issues. Understanding and combating these cold-weather challenges is crucial for optimal diesel performance

Understanding Cold-Weather Diesel Challenges

As temperatures drop in Portland, diesel fuel, known for its efficiency and power, encounters an Achilles’ heel—the tendency to gel. This gelling occurs primarily due to the crystallization of the waxes naturally present in diesel. When these waxes crystallize, they can clog fuel filters and lines, hindering fuel flow and causing engines to struggle or even fail to start. This is a common situation for those familiar with traveling in colder areas of Oregon, emphasizing the importance of preventive measures to ensure the uninterrupted performance and reliability of diesel machinery and vehicles.

The Science Behind Fuel Gelling and Wax Crystallization

Diesel fuel has a natural reaction to cold weather because it contains paraffin waxes. These waxes are helpful in warm weather because they provide energy to the fuel. But when temperatures get colder, the waxes start to solidify, just like water turns into ice when it freezes. As the temperature drops, the waxes form crystals that grow larger and make the fuel thicker.

This process is called crystallization, and it makes the fuel less fluid, which can cause gelling. When diesel fuel gels, it becomes thick and sludgy, like a semi-solid. This makes it difficult for the fuel to flow through the engine, which can lead to serious problems for diesel engines.

The formation of these wax crystals is a big issue because they can clog fuel lines and filters, stopping the engine from running properly. When fuel can’t move smoothly through the system, engines can stall or fail to start altogether. This is why gelling is such a major concern for diesel engines during cold weather, and it’s important to find solutions to prevent it from happening.

Introduction to Cold Flow Improvers

To address the issue of gelling, additives known as cold flow improvers have been developed. These chemical additives prevent diesel from gelling in cold temperatures by targeting wax crystals in the fuel. They keep these crystals small and dispersed, ensuring diesel remains fluid and pumpable. This functionality is crucial for maintaining smooth engine operation and fuel system efficiency in cold climates, such as those experienced in Portland and other areas of Oregon, without altering the diesel’s inherent properties.

How Cold Flow Improvers Work

When diesel fuel gets cold, it can start to thicken because wax crystals form inside it. These wax crystals can grow and stick together, which makes the fuel hard to flow through the engine. Cold flow improvers are special additives that are designed to stop this from happening.

At a molecular level, cold flow improvers change how diesel behaves in cold temperatures. They target the process where wax crystals form and grow. Normally, when it gets cold, these crystals start to connect with each other, and that can cause clogs in fuel filters or slow down fuel flow. But when cold flow improvers are added to diesel, they act as nucleation inhibitors. This means they stop the wax crystals from growing too big or interlocking with each other.

Because of this, the fuel stays fluid and can still flow smoothly, even when temperatures drop. Cold flow improvers help ensure that diesel engines run properly in cold weather by keeping the fuel from gelling up. This keeps fuel filters from clogging and helps the engine perform better, so vehicles and equipment can operate reliably, even in the winter

Benefits of Cold Flow Improvers

Cold flow improvers have proven valuable for businesses in Portland, OR, that rely on diesel-powered equipment, especially during the chilly, wet winter months. Here are a few examples of how these additives can benefit equipment performance:

1. Reduced Fuel Gelling in Cold Temperatures

- Problem: Diesel fuel can start to gel when temperatures dip, leading to clogged fuel lines and filters. This is especially problematic for trucks, construction equipment, and other diesel-powered machinery that operates outdoors.

- Solution: Cold flow improvers lower the temperature at which diesel fuel thickens, preventing gelling. This keeps machinery running smoothly during cold snaps, even when temperatures fluctuate widely across Portland’s winter.

2. Improved Fleet Reliability for Delivery and Transport Services

- Problem: Delivery trucks and transport services often face delays or downtime due to fuel issues in the winter, as fuel flow can slow or stop altogether.

- Solution: By using cold flow improvers, delivery companies keep fuel flowing reliably in suboptimal weather. This reduces the risk of late deliveries and unplanned maintenance, helping fleets stay on schedule and lowering operational costs.

3. Enhanced Performance for Emergency Backup Generators

- Problem: Many commercial and industrial businesses in Portland rely on backup generators to kick in during outages, but generators need reliable fuel flow to work properly in cold temperatures.

- Solution: Adding cold flow improvers to generator fuel storage ensures that fuel remains liquid and usable during winter, helping businesses maintain critical operations in power outages.

4. Lower Maintenance Costs for Construction Equipment

- Problem: Heavy equipment used on construction sites, especially in winter months, can suffer from fuel blockages, leading to breakdowns and costly repairs.

- Solution: Cold flow improvers prevent fuel line blockages and improve equipment reliability, reducing maintenance expenses and keeping projects on track, even during Portland’s colder periods.

By adding cold flow improvers, businesses across Portland can minimize disruptions due to cold weather, maintain reliable equipment performance, and reduce winter-related repair costs. This small addition to fuel management can make a significant difference in operational efficiency and reliability during the cold months.

Monitoring Fuel Usage

Using cold flow improvers offers several essential benefits for diesel engines in cold weather:

Prevent Fuel Gelling and Filter Clogs

These additives keep wax crystals small, preventing filter blockages.

Enhance Fuel Flow and Engine Performance

Improved fluidity leads to better engine efficiency and reliability.

Prevent Downtime

Using cold flow improvers can help avoid costly equipment downtime due to fuel system gelling.

Ensure Operational Reliability in Cold Climates

These additives are vital for the consistent performance of diesel engines in winter conditions.

Cost-Effective

Cold flow improvers enhance fuel efficiency and reduce maintenance needs, offering long-term cost savings.

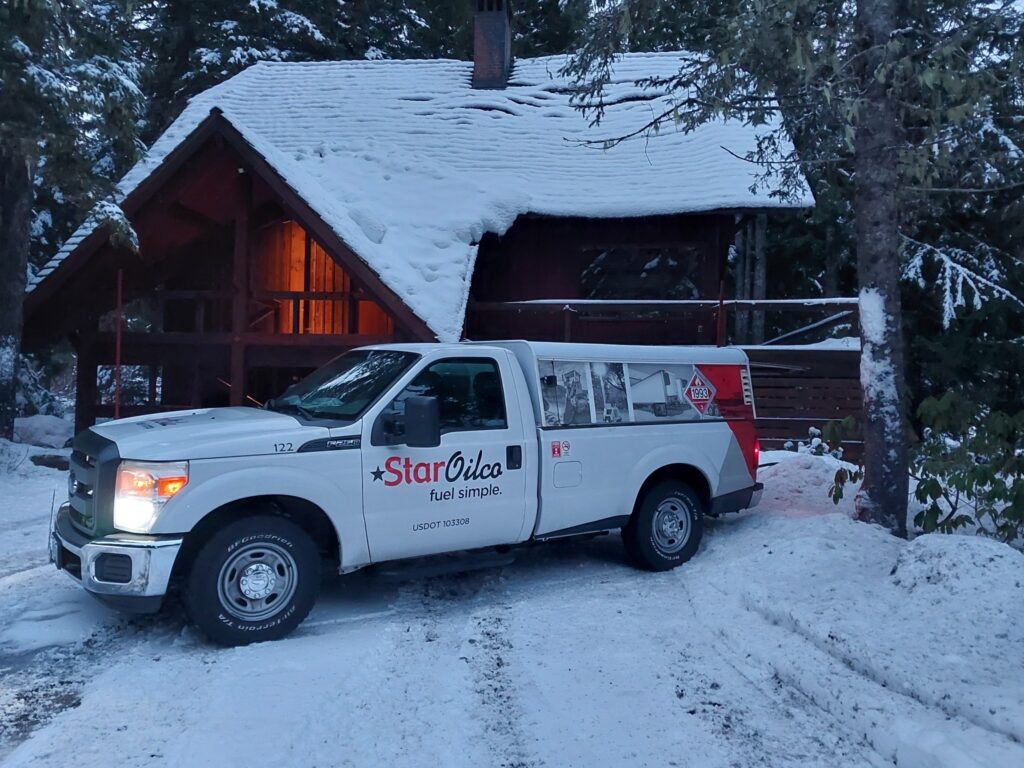

Star Oilco’s Winterized Diesel Offering

If you’re purchasing fuel in Portland or throughout Oregon, consider sourcing from a fuel supplier that provides winterized diesel, like Star Oilco. Star Oilco’s winterized diesel includes these crucial additives, ensuring you have the right protection against gelling. This can save you time and help maintain optimal performance during the cold months in the Pacific Northwest.

Star Oilco is a trusted fuel supplier based in Portland, Oregon, dedicated to delivering high-quality fuels and related services to both commercial and residential customers. With decades of industry experience, the company offers a wide range of solutions, including heating oil delivery, off-road diesel, cardlock fueling systems, and emergency backup fuel options. Committed to sustainability, Star Oilco also provides biodiesel and renewable diesel to reduce environmental impact while supporting the energy needs of the Portland community. From optimizing fleet fuel efficiency to ensuring reliable heating in colder months, Star Oilco prioritizes customer satisfaction with tailored, dependable fuel solutions for businesses and homeowners alike.

Ensuring the Right Dosage

The effectiveness of cold flow improvers depends heavily on using the correct dosage. Over- or under-dosing can lead to suboptimal performance or damage to the fuel system. Consulting with a fuel specialist is recommended to determine the appropriate amount of cold flow improver needed for specific applications, taking into account the fuel properties and temperature forecasts.

Cold flow improvers are essential for diesel engines during winter, especially in Portland and Oregon, ensuring optimal performance in cold climates. They prevent fuel gelling and wax crystallization, maintaining fluidity and engine efficiency. Their role is vital in providing operational reliability and cost-effectiveness for those reliant on diesel fuel during colder months. Embracing these improvers allows you to face winter’s challenges confidently, safeguarding engine performance and longevity.