Make And Keep Your Diesel Fuel A Lot More Clean

Make And Keep Your Diesel Fuel A Lot More Clean

What is Clean Diesel?

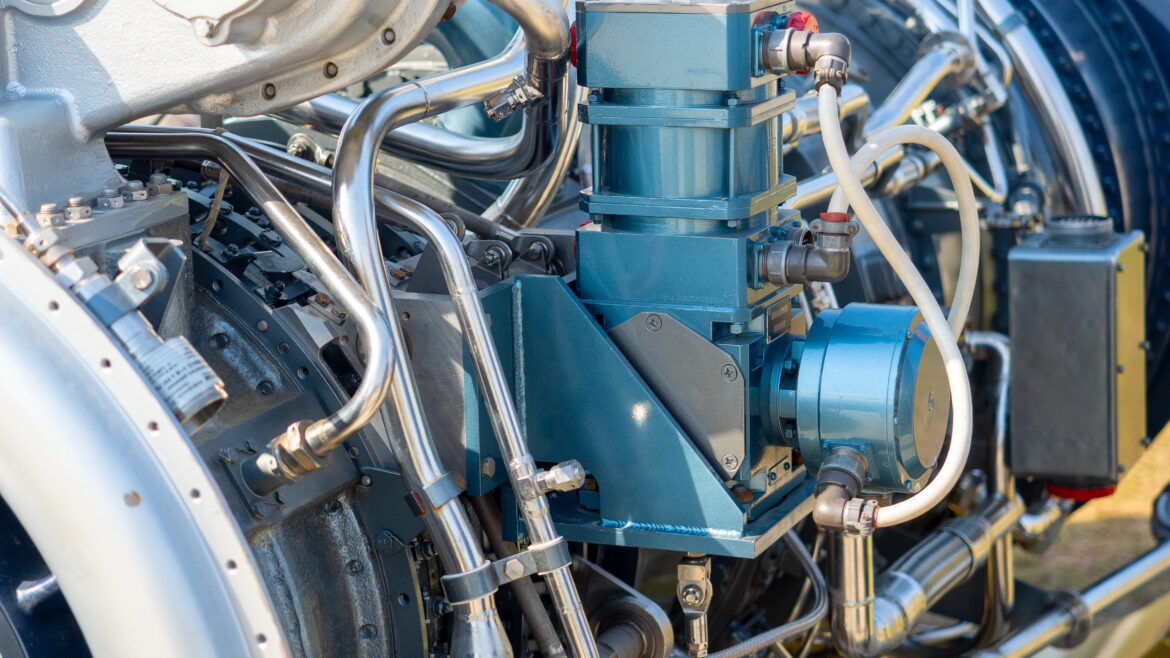

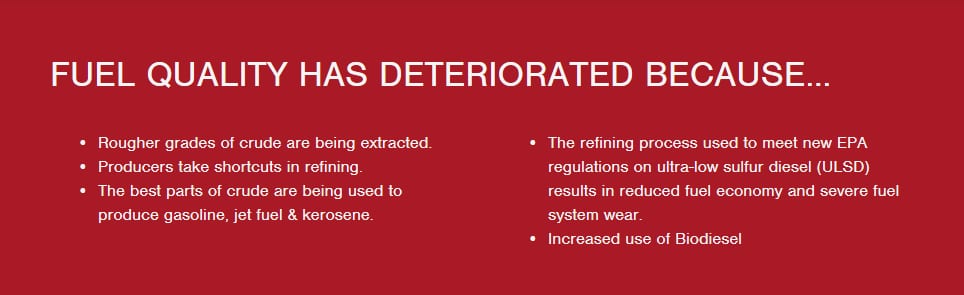

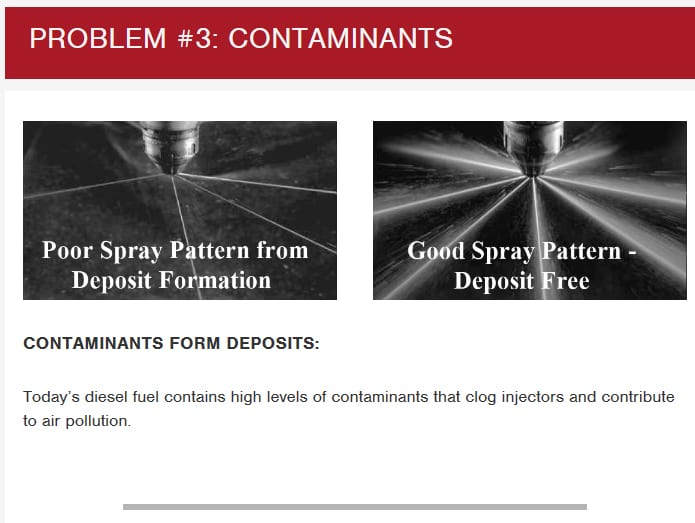

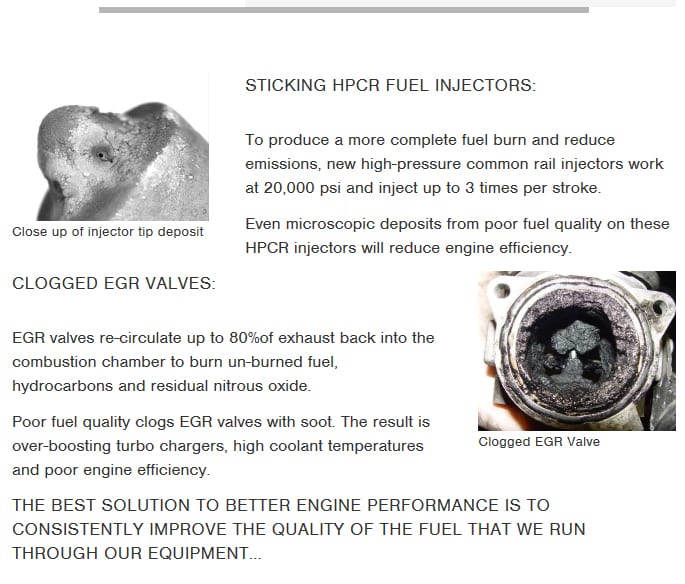

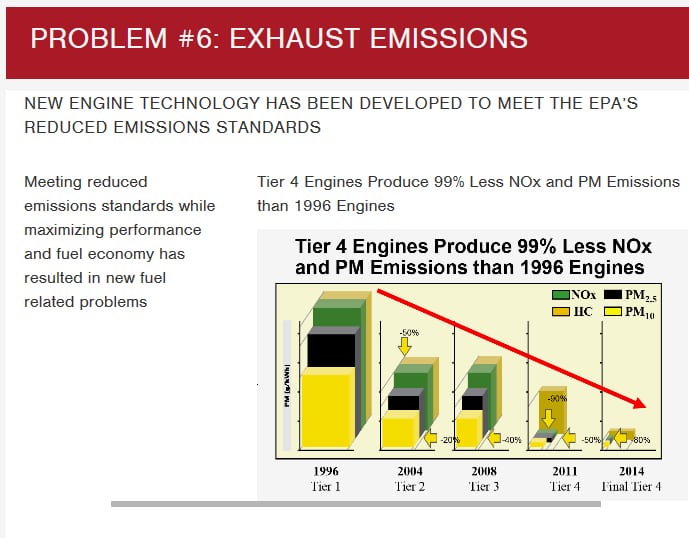

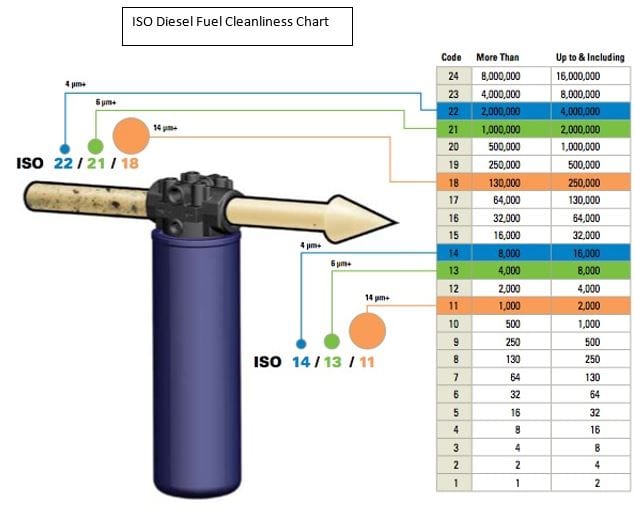

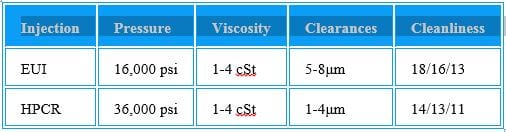

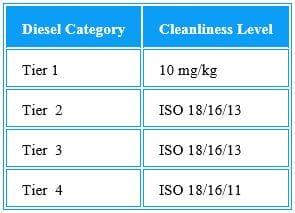

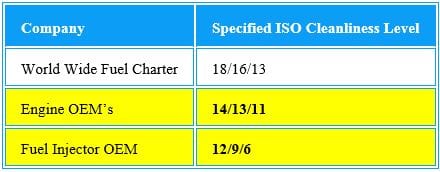

Clean diesel is free of the contaminants that harm modern diesel engines. Today, there is a gap between ASTM diesel standards and the ISO cleanliness standards needed for use in high pressure common rail engines. Anyone operating a modern clean diesel engine is seeing the effect, including injector replacement, DPF regeneration, and a host of other fuel quality related maintenance concerns we never saw twenty years ago. On top of all of that, today’s refined diesel fuels are less storage stable than ever before. What is on the bottom of your bulk tank can also complicate matters further. When diesel is bought wholesale, it typically meets and exceeds ASTM required industry standards, but almost always requires additional filtration to avoid excessive engine wear and premature part failures.

Having clean diesel requires an additional amount of care. Namely, you need to make sure that the fuel is aggressively filtered at 4 microns to catch the microscopic particles that are big enough to damage your modern diesel engine’s high pressure fuel rail system. Furthermore, clean diesel is fuel that is free of water and stabilized with Premium Diesel to guarantee no bacteria, yeast and other creatures can grow and further contaminate the saddle tanks on your trucks.

For more on clean diesel, see Donaldson’s description of “The New Clean” for an in-depth explanation of what ISO cleanliness and filtration mean for your diesel fleet.

Making Diesel Cleaner!

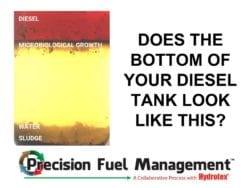

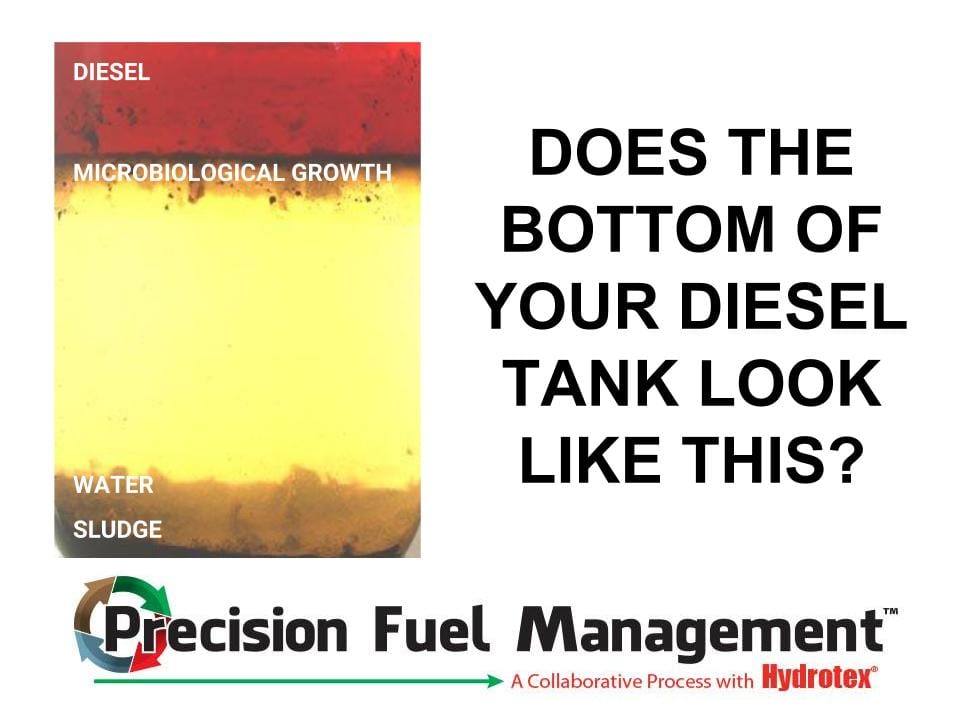

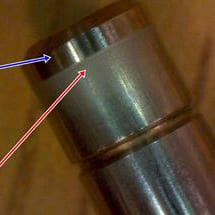

Knowing the quality of your fuel is the first step. This is done by taking samples off of the bottom of your bulk storage, as well as a representative sample from your fuel dispenser. Lab tests of those samples will tell you if you have water, biological growth, or dirt issues with your storage. The contaminants in the tank being sampled are almost always visible, which is to say that they look horribly ugly. If your fuel quality assurance has been on autopilot, do not be surprised if you find this. After gathering knowledge about your fuel, the next step is to get your fuel quality clean.

Filtration and tank bottom sampling is the start. Beyond that, the only way to improve your fuel quality performance is to filter your fuel, ensure water is not getting into the tank through condensation, and additize it with a Premium Diesel additive to upgrade the performance of the fuel. Many fleets today are seeing injector wear and continual problems with particulate trap maintenance. This is a combination of water in fuel and microscopic particles not captured by a 10 or 30 micron filter used at most diesel dispensers. You have to filter more aggressively than this.

Clean, Dry, and Premium Diese

Where To Start?

The first step is sampling your bulk diesel tank. We check your bulk tank for water and dirt to make sure and meet the specifications your engine is built for. Star Oilco can help by providing a complementary diesel test for those fleets interested in taking control of their fuel quality assurance. Usually when testing fuel, we take a sample off of the tank bottom as well as a representative sample out of the fuel dispensing nozzle.

What we usually find is ASTM specification diesel fuel (it meets ASTM spec) that is higher than you’d want (still in spec) for water with far more dirt than the OEM’s would want to see in your engine. This dirt fails to be within the “ISO Cleanliness” specifications recommended by engine manufacturers. Usually, we also see water on the bottom of the fuel tank, which is a likely source for future or current biological growth in your fuel tank.

Star Oilco can help you fix this! The first step is to sample your fuel tank.